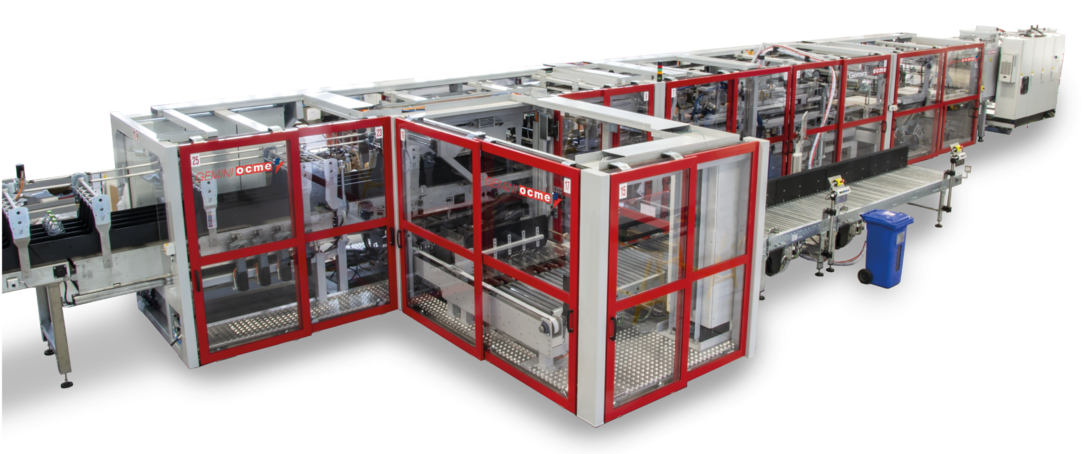

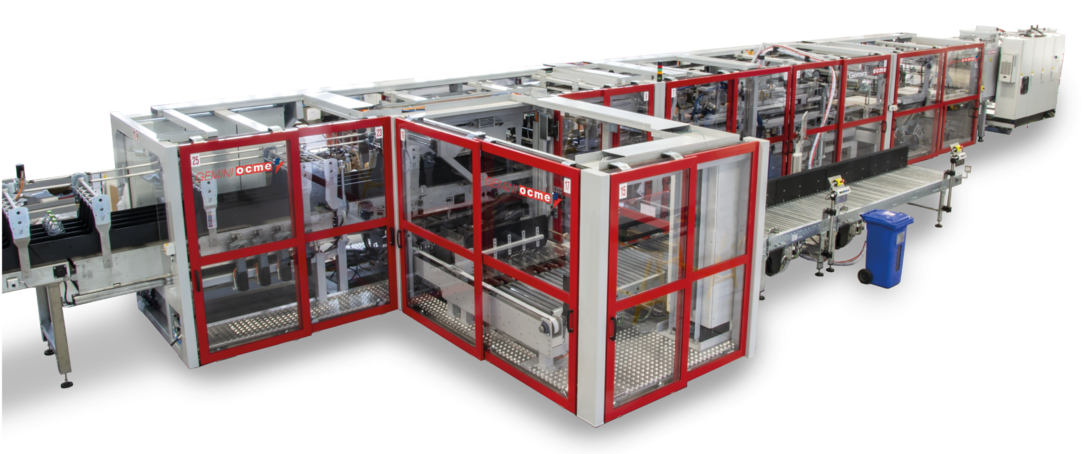

Gemini HT Combined machine: wrap-around carton packer and shrink-wrapping

All the advantages of shrinkwrappers and wraparounds concentrated into one unique solution for producing high quality packages. Gemini HT is OCME's combined machine designed to process both wrap-around cartons and trays, with or without film.

close

product benefits

Excellent accessibility for operators and maintenance staff

Possibility to process various types of containers

PET bottles, Glass bottles, HDPE containers etc

High level components complying with highest safety standards

Reduced glue consumption

Very compact carton

Secondary Packaging

Film with tray

Only film

Cartons

overview

Gemini HT combines all the advantages of Altair wrap-around packers and Vega shrink-wrap packers. Our focus is on high efficiency and high productivity installations, destined to various product sectors, such as Edible oil, Lube oil and Beverage.

Gemini models are divided into 3 categories: Gemini X for speed up to 30 packs / minute, Gemini HT for average speed of 40, 50 and 60 packs/minute, Gemini Advance series for speed up to 70 and 80 packs/minute, Gemini HT series for speed up to 100 packs/minute

The machines can process cartons with a thickness between 1.5 and 5mm.

option & data sheet

Cygnus - automatic blank feeding

The capacity of the blank magazine can be fed with a robotic blank picking system that move blank into magazine directly from the pallet.

The pallet with blanks only needs to be positioned on the conveyor by the fork-lift truck driver who removes the wrapping

strap, after which the machine runs completely automatically for a long time. The operator is thus relieved of the need to lift stacks of blanks manually.

electronic selection unit

OCME has developed a solution called "electronic selection" that allows us to select incoming products without any contact so as not to damage the external surface in any way or, even worse, the label, which is totally devoid of traditional pegs: by independently motorizing each row of incoming products, it is possible to channel and dose - according to the format being processed - the containers without contact pressure.

With this system, format changeover also becomes simpler as there is no need to physically change the traditional peg bars.

Partitions

In some circumstances it is necessary to provide further protection to the product inside the case.

Cardboard partitions are used for this and they are inserted during the machine operating cycle.

Altair is able to integrate two different technologies depending on the protection required: it can insert traditional partitions or pre-formed partitions.

• The first type, typically manufactured in corrugated cardboard, offer increased resistance against impacts and are therefore recommended for products which have to be transported over long distances. Traditional partitions are inserted from various feeding magazines that are appropriately placed along the packaging line.

• The pre-formed partitions use low-cost, preassembled, solid pressed cardboard, which protects the containers and also their labels from abrasion. The pre-formed insertion system consists of a side magazine, readily accessible for re-fill, and a S.C.A.R.A. robot which picks the partition from the magazine, opens it and then places it between the containers as they run down the line.

Integrated handle applicator

With the integrated OCME handle applicator located before shrink wrapping module, the customer has two machines in one.

The machine operates with single, double or triple track, with rapid format changeover, and high efficiency in applying the adhesive tape on film.

Energy saving kit

The kit consists of a series of motorized curtains at the tunnel inlet and outlet which close when the shrink wrapper packer is not receiving any products from the line. Heat is preserved inside the tunnel by closing the oven inlet and outlet, slowing down conveyor and cooling fans

and reducing the current drawn by the heating elements to minimize dispersions and energy consumption.

Automatic reel SPLICING DEVICE

This optional feature reduces idle time especially on highly automated systems in which the operator is responsible for supervising multiple machines. When a new reel is inserted, the leading edge of the film simply needs to be placed in position and the machine automatically splices the ended film and restarts with the new one One without the intervention of an operator.

External reel loader

In order to facilitate the operator in loading the shrink film reels, the machine can be equipped with an external loader which guarantees a high level of ergonomics. The loader is completed with an automatic splicing unit.

Gas shrink tunnel

Shrink tunnels can be equipped with burners - compatible with both natural gas and LPG - instead of the traditional electric heaters for heating the air. This configuration uses state-of-the-art porous burners capable of burning the fuel without the actual presence of a flame. In this way, the combustion process is extremely controlled and it is possible to avoid the emission of unburned or partial products harmful to humans into the working environment.

Size changeover

To make the size changeover easy, quick and repeatable, machine has several customizations that allow simple adjustments without tools.

The repeatability of each adjustment is guaranteed by counters and numerical tables which correspond to an specific values for each size.

Adjustments are totally automated on the motorized version and the operator intervention is required only to start the procedure and for a minimum number of the operations.

A step-by-step guided procedure, complete with photographs, may be uploaded onto the operator panel to help the operator during size changeover. In this way, size changeover becomes easy even for operators without specific training, who just need to carry out all the steps in the correct order.

In the model with the PDA device, the machine adjustment points are identified by barcodes. A PDA reader scans the code that reproduces the description of the adjustment to be made and the corresponding value.