This has been our goal since 1954 when we started as small workshop of machines for Food industry.

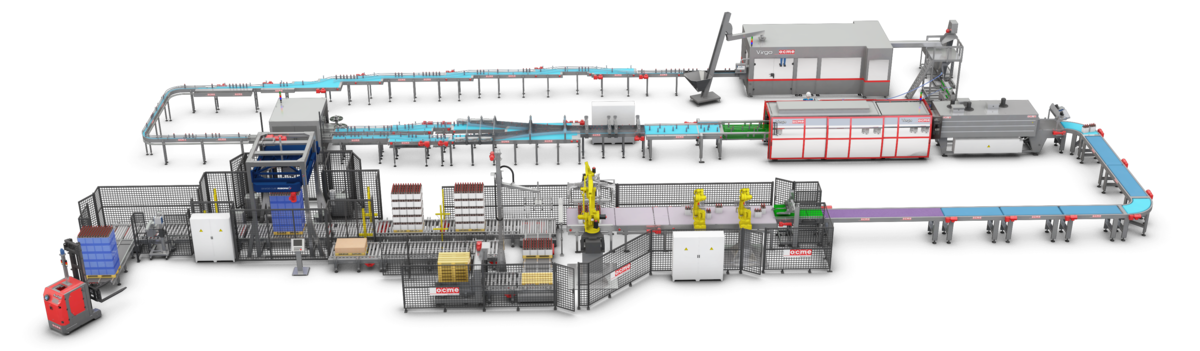

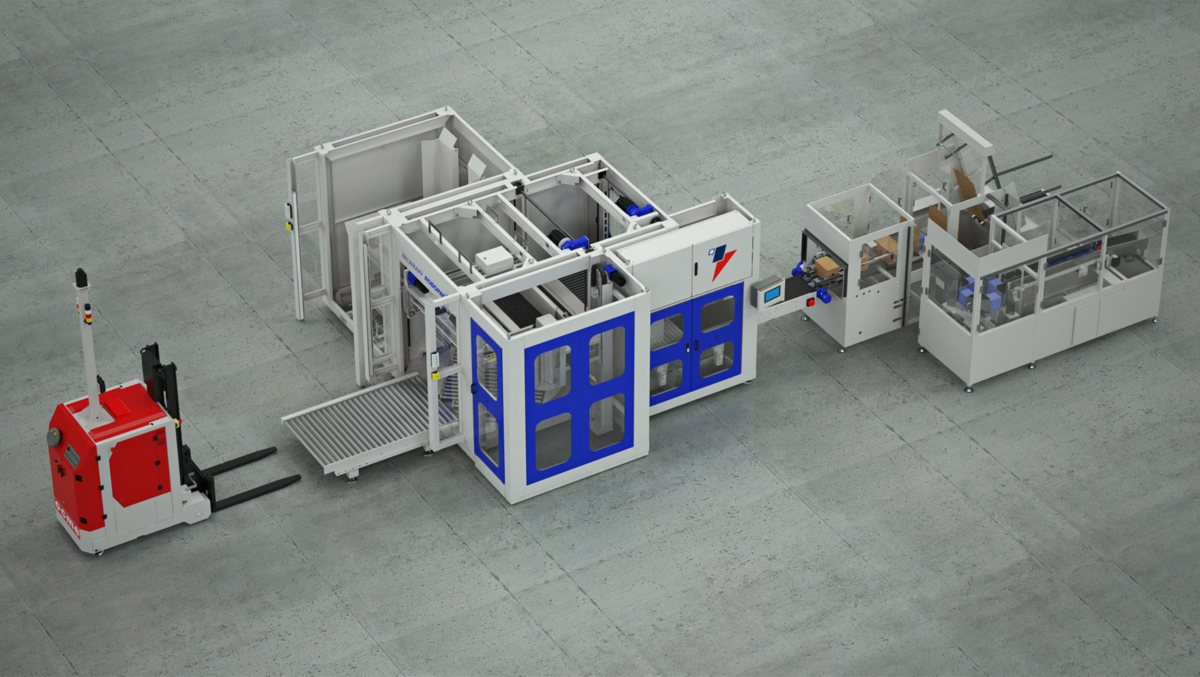

Since then we have grown into a turn-key supplier for Food sectors because we want to help our customers with everything they need to automate their production lines.

Case studies

Technologies for Incobrasa and USAID at the service of humanitarian projects

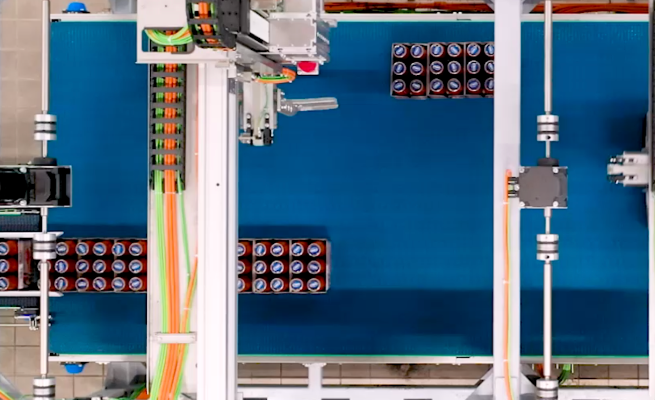

OCME solutions have contributed to the packaging of materials and supplies that USAID has assigned to the United Nations WFP project, which received the Nobel Peace Prize in 2020.

Case studies

CONSERVE ITALIA

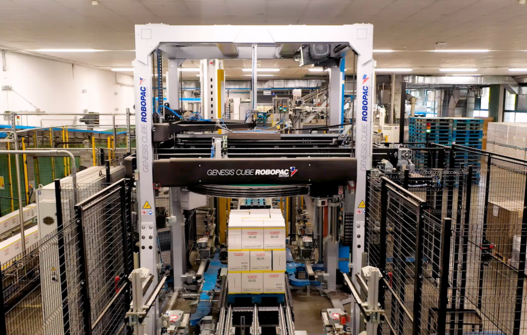

The collaboration between Robopac and Conserve Italia is historical, with actions mainly targeted at the French plants and Pomposa plant - one of the largest food factories in Italy - and aimed at the replacement of individual machines. In 2017 Robopac carried out a more complex project, which was the integration of a TC500 CW for glass bottles containing tomato puree to the already existing line.