An extremely competitive company based in the Republic of San Marino, which owes its success to the high level of quality that has been achieved thanks to a family-run business focused on people, customers and their satisfaction.

With four production facilities and more than 700 employees, the company has an annual turnover of €230 million and focuses on the use of state-of-the-art materials and technologies, with constant investment in order to guarantee highly technical and functional products.

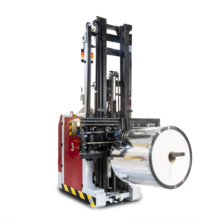

The basis of the philosophy behind this San Marino-based company, which chooses its partners for their level of innovation, professionalism and after-sales service, is building relationships of trust. Relying on Aetna Group’s expertise in packaging and specialisation in end-of-line and logistics, SIT Group recently introduced OCME laser-guided vehicle solutions to make it easier to handle raw materials and semi-finished products. An efficient system needed to be found that was capable of handling specific items, such as reels, to feed and unload the machines flexibly, safely and quickly. By implementing OCME solutions, the company, which previously used forklift trucks to handle around 600/700 reels per day, has managed to minimise the risks associated with mechanical handling and has improved staff working conditions: by eliminating the semi-manual transport of large reels, it was possible to reassign tasks to more satisfying activities and increase the safety of the entire facility.

Implementing AGV (Automated Guided Vehicle) systems at the various SIT Group facilities led to an immediate performance upgrade in terms of speed and efficiency, making it possible to dedicate time and resources to value-added activities, resulting in an economic return on the investment. The greater tidiness within the facility was also perceived positively by all staff.

AGVs are laser-guided vehicles that move independently by means of a laser triangulation system that allows safe movement, both for machines and operators in the production department. This system allows AGVs to calculate and determine the most suitable route in relation to the overall logistical situation at any time, and always independently and automatically.

For the SIT Group, this was an important choice, focused on an innovation path that involves the entire operating system and that has enabled the company to position itself among the most advanced companies in the sector. Relying on OCME's experience and professionalism, SIT Group has equipped its logistics division with automated solutions capable of interacting with existing systems and infrastructures, improving warehouse management and optimising material flows.