We are recognized as being a systems manufacturer that meet the requirements

of its customer, ensuring high quality, reliability and safety.

Being a company identified as a technology leader is only possible thanks to constant product's innovations and flexibility in business processes.

This objective is pursued through the analysis of the needs of the customers and the identification of more appropriate technical solutions, continuous investments for innovation and continual improvement of products, their industrialization and processes to meet customers’ expectations.

Discover some of our

best practices orcase histories to see how we can support you

as a partner:

Castrol awards Aetna Group China the title of “Excellent Partner”

Tianjin. China, 30 October 2025Castrol (BP) awards Aetna Group China the title of “Excellent Partner” for strategic collaboration and advancement of automation in the lubricant sector

Aetna Group and Mahou San Miguel: quality and flexibility are at the core of a trusted partnership

Driven by a constant pursuit of innovation in production processes, Mahou San Miguel - Spain’s leading beer producer - remains committed to using Aetna Group’s advanced packaging technologies to further enhance the efficiency of its glass and can packaging lines.

Birra Peroni: innovation and flexibility, thanks to Aetna Group solutions

Birra Peroni, a historic name in Italy’s brewing tradition, continues to invest in cutting-edge technologies to further improve the efficiency of its production processes.

Cedral tassoni and Aetna group: tailor-made designs for an enhanced end-of-line

After a careful analysis of production requirements and industrial layout, the Aetna Group team identified the Robopac Helix 3 EVO and OCME Perseus as the most suitable solutions in terms of reliability, efficiency and level of automation.

Varun Beverages Limited enhances its technological expertise in India with Aetna Group

Varun Beverages Limited (VBL) - an Indian multinational company with a strong international presence - is regarded as one of the world's largest beverage bottling and distribution companies.

Packaging innovation and efficiency: Refresco italia's transformation with the Aetna Group

The collaboration between Refresco and the Aetna Group has led to remarkable results in the optimisation of packaging and wrapping lines. The introduction of OCME and Robopac technology solutions has significantly improved operational efficiency, stabilised pallets, reduced bottle wear and optimised bottle reuse.

Papadopoulos: OCME and Robopac offer flexibility and optimisation for packaging and palletising processes

Thanks to the integration of these two machines, the synergetic work between Aetna Group and Papadopoulos has produced significant results in terms of increased productivity and reduced downtime. This has allowed the major Greek player to further consolidate its leadership.

Hellenic fine oils chooses OCME for a new filling and pallet line

OCME is a technology partner which collaborates with one of the leading companies in Greece, Hellenic Fine Oils of Corinth, for the production and bottling of olive oil and seed oil.

Tailor-made solutions: Aetna group provides complete end-of-line Thermal Insulation to improve time, productivity and efficiency

After a research and scouting phase, the choice fell on the technologies and technical know-how of Aetna Group. The latter - thanks to proactive listening and the ability to create tailor-made solutions, provided a comprehensive fleet of machines to meet the customer's requirements.

DE CECCO APPOINTS OCME TO PROVIDE THE FLEXIBILITY REQUIRED BY A GLOBAL FOOD LEADER

In the production area of the Ortona plant, De Cecco turned to OCME with the request to maximise the efficiency of the palletising process while at the same time guaranteeing great flexibility (qualities which are widely desired in the food sector), in order to handle on demand line requirements

Heineken: packaging process optimisation with ocme and robopac solutions

At the heart of this collaboration is Heineken's need to improve the packaging process efficiency and speed to meet growing market demand. Furthermore, over the past few years, the wrapping area has been optimised to make it even more competitive.

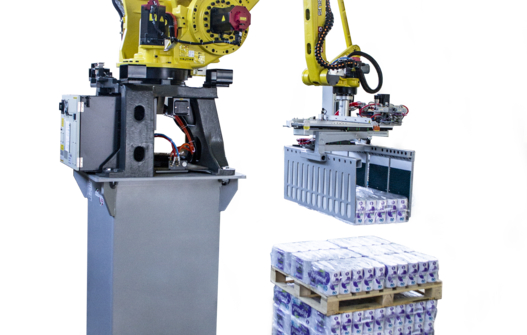

USA: ROBOPAC AND TOPTIER BUILD SUNTADO'S NEW FOOD-DAIRY PLANT

Suntado, a leader in the co-packing of dairy beverages, has recently completed the installation of six secondary packaging lines at its plant in Burley, Idaho, made up of Robopac and Toptier solutions.

Advanced technologies for empty containers: Aetna group is synonymous with innovation, stability and protection

Aetna Group responded with advanced technologies to ensure the durability of delicate packages made into various shapes and from different materials, which are, then, handled in their empty form.

ARLA FOODS CHOOSES ROBOPAC IN ITS HIGH-SPEED PACKAGING

Arla Foods, a leading dairy producer, chose Robopac's Prasmatic TC 800 CW range for packaging optimization, enhancing efficiency with speeds of up to 85 packs per minute.

DANISH CROWN: WHEN FLEXIBILITY AND SERVICE MAKE THE DIFFERENCE

The success of a relationship with its customers is measured on several fronts and the case of Danish Crown is a typical one.

THE COCA-COLA FEMSA DISTRIBUTION CENTRE IN URUGUAY RELIES ON OCME TO OPTIMISE LOGISTICS OPERATIONS

In collaboration with OCME, Coca Cola Femsa successfully implemented an advanced automated system based on Auriga 30 CT laser-guided vehicles for the management of the flow of empty bottles and finished products, demonstrating great expertise and a spirit of collaboration.

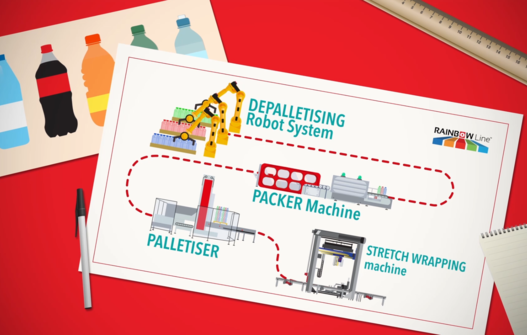

GOYA FOODS SPEEDS UP ITS LINES WITH ROBOTICS FROM ROBOPAC AND OCME

The end of line system was designed and implemented using seven technological solutions, among the fastest and most advanced of the entire range of products available within the Group. Let us see which ones: Depalletisers, tray packers, palletisers and wrapping machines from OCME and Robopac.

CEPSA, OCME AND ROBOPAC TOGETHER FOR AN EFFICIENT END-OF-LINE IN TERMS OF PRODUCTIVITY AND SUSTAINABILITY

CEPSA turned to Aetna Group for its new lubricating oil packaging line in San Roque (Cadiz): automation, digitisation and attention to energy consumption are aspects that are fully reflected in this new state-of-the-art plant.

SIT GROUP CHOOSES OCME AGVs AS A SYNONYM FOR MAXIMUM LOGISTICAL EFFICIENCY

The value of flexible plastic packaging for the European food and non-food consumer market bears the SIT Group brand, one of the leading players in flexible packaging.

Greci Industria Alimentare Dimac Nova: shrink wrapper for tomato cans

GRECI INDUSTRIA ALIMENTARE CONFIRMS ITS TRUST IN AETNA GROUP WITH A TECHNOLOGICAL UPGRADE

SANO INTERNATIONAL AND AETNA GROUP: TWO LEADERS IN THE TISSUE INDUSTRY MEET

Sano international is an Israeli company with a long and successful history behind it, which today manufactures and markets over 500 Home & Personal Care products worldwide. Innovation, sustainability and quality are the core of the company's business, which is conducted in three production plants in Israel and one in Romania.

Medina dairy and Freshways invest in Robopac end of line solutions

Since merging in 2021, with Medina Dairies Ltd, Freshways is now one of the UK leading dairy suppliers, with a number of UK facilities combining to process over 500 million litres of milk per year.

Complete end-of-line for the tissue industry installed at FUTURA LINE

The customer's request was clear: to propose and design an automatic end-of-line system and logistic management of products on pallets, starting from a green field. OCME has been able to carry out this project by automating all the needs of the Italian Futura Line Group.

NORSK KYLLING

The supply request concerned 15 Sotemapack automatic packaging machines of the Wrap Around WA20 series. Thanks to the different solutions available, these machines are able to process a large quantity of products: thermoformed trays, flexible containers and flowpacks, packed in different types of secondary packaging.

Trevalli Cooperlat

Trevalli Cooperlat chooses Robopac Packers for the secondary packaging line

12 MORE WRAP AROUND MACHINES IN DE MATTEIS FOOD PLANT

The collaboration between Sotemapack and De Matteis Alimentare - one of the main Italian producers of durum wheat pasta - started in 2010 with the first supply of advanced packaging machines.

THE OCME LGVs SYSTEM JOINS VIOLETA

The company decided to rely on OCME's automatic solutions, to improve the performance of its warehouse and the working environment. The answer given by OCME in order to meet the needs of the industrial lay-out was providing two Auriga high-precision LGV lift trucks

CONSERVE ITALIA

The collaboration between Robopac and Conserve Italia is historical, with actions mainly targeted at the French plants and Pomposa plant - one of the largest food factories in Italy - and aimed at the replacement of individual machines. In 2017 Robopac carried out a more complex project, which was the integration of a TC500 CW for glass bottles containing tomato puree to the already existing line.

LGV HAS BEEN "LEGOlized" BY THE UNIVERSITY OF NOTTINGHAM

The University of Nottingham is working on several projects with OCME’s AURIGA and have recently developed an amazing video with the vehicle made of LEGO! This stop frame animation uses lego models to show the operation of the research project at the University

COLLABORATION WITH EXXONMOBIL Chemical AND RKW TO DEVELOP NEW PRINTED FILM CREATED WITH RECYCLED POLYMERS

In a new step towards sustainable packaging and technological evolution, OCME has worked together with suppliers ExxonMobil Chemical and RKW Group to develop a new type of high quality film made with virgin polyethylene from ExxonMobil and post-consumer recycled PE content.

Complete “turnkey” solution for Iconic Lubricants

The need to modernise plants and increase their functionality and productivity led Iconic Lubrificantes to look for a single, reliable partner that could guarantee the achievement of the objectives set. OCME was the right answer.

ENOITALIA CHOOSES OCME'S LGV AURIGA VEHICLES

OCME supplied Enoitalia with 11 automatic Laser Guided Vehicles (LGV) of the Auriga series, which includes two models.

Technologies for Incobrasa and USAID at the service of humanitarian projects

OCME solutions have contributed to the packaging of materials and supplies that USAID has assigned to the United Nations WFP project, which received the Nobel Peace Prize in 2020.

Lucas Oil a prestigious customer in the United States lube oil industry.

OCME lands a prestigious new customer in the United States lube oil industry. Based in Corona, California, Lucas Oil, has installed the Italian company’s filling and secondary packaging solutions for its range of lubricants and additives for automotive applications.

The South American tissue industry chooses Robopac and OCME technology

OCME has been charged with the development of end-of-line solutions for packaging by one of the most important tissue companies in South America

olitalia

With a widespread presence in over 120 countries around the world, Olitalia is a company specialized in the foodservice of oils and vinegars based in Forlì.

Jafora entrusts OCME with palletizing and wrapping

Jafora is an important producer of soft drinks and juices from Israel, recognized worldwide for its technical expertise and its excellence in the research of the latest technological solutions for its plants.

Logistics and end-of-line for Caviro

A complete end product handling system, spanning palletising to preparation of the shipping bays, all perfectly in synch with the automatic warehouse located onsite.

VEGA SHRINK-WRAPPING INSTALLED AT COCA - COLA HBC ITALIA

An installation was carried out of Vega HT at a well-known customer’s plant: Coca-Cola HBC Italia, located in Oricola, which is part of the Coca-Cola Hellenic Bottling Company