VBL is PepsiCo's main franchise partner outside the United States, operating in more than 30 countries, with a particularly strong presence in growing markets such as India. This is where the company operates more than 30 facilities.

In order to support its growth and ensure high standards of efficiency and quality in its production processes, VBL has invested significantly in state-of-the-art technology, selecting the leading provider of automation and end-of-line packaging: Aetna group.

ROBOPAC AND OCME INNOVATION IN VBL FACTORIES

Thanks to the strong partnership between VBL and Aetna Group, the Indian giant has developed a successful innovation strategy.

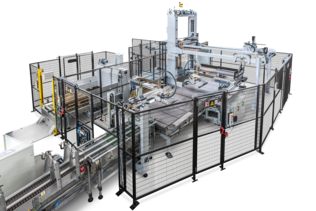

In particular, several production lines (supplied by Robopac and OCME, the main brands of the Aetna Group) have been installed at the Supa plant in Pune - one of the most modern and technologically advanced in the group - aimed at optimising the packaging and palletisation process.

Four lines dedicated to Carbonated Soft Drinks were equipped with OCME solutions. These include the Vega N80SP automatic shrink wrapper, the Perseus LF2C SP anthropomorphic robot palletiser, and the Helix Universal automatic rotary arm wrapping machine. These solutions benefited from the support of the subsidiary Aetna Group China. This was established by merging the two historic subsidiaries Robopac China and OCME China, to promote an international strategy while maintaining a local-for-local strategy capable of meeting the needs of local manufacturers.

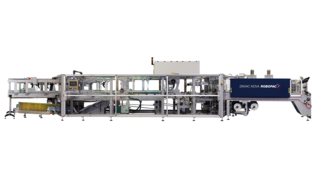

The Dimac Nova 60P tray packaging technology was chosen to set up both a Water line and an aseptic line. All this was completed by the Perseus LF2C SP palletiser and the Helix Universal automatic wrapping machine.

The integration of Robopac and OCME solutions has enabled Varun Beverages to increase production levels as well as improve process flexibility and quality. The lines, developed to respond quickly to market needs, minimise downtime and optimise the production cycle. Furthermore, the packaging efficiency meets the high standards required by the aseptic line, respecting the essential safety features for contamination-sensitive beverages.

QUALITY AND AUTOMATION: THE VALUES OF AN ESTABLISHED PARTNERSHIP

The widespread adoption of Aetna Group technologies is not limited to India. In fact, since 2022, Varun Beverages has purchased and installed a further 18 Robopac and OCME machines at its international locations.

This is a significant testimony not only of the wide distribution of VBL plants throughout the world, but also of the commitment to quality and innovation that the trust and partnership with Aetna Group has provided over time.