DESIGN A TAILOR-MADE DEPALLETIZING SOLUTION THAT PERFECTLY MATCHES YOUR AVAILABLE SPACE, ENSURES OPTIMAL ACCESSIBILITY FOR OPERATORS AND MATERIAL FLOW, AND GUARANTEES SAFETY, ENERGY SAVINGS, AND SYSTEM EFFICIENCY.

Our mission is not only to provide reliable, high-tech depalletizing machines, but to deliver the most accurate and efficient solution based on your real operational needs.

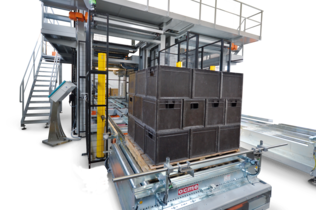

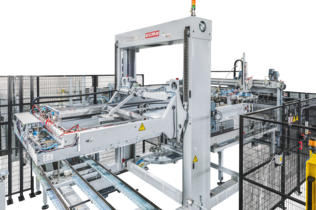

We engineer complete depalletizing systems that integrate robotic or traditional modules, suitable for any production scale. Whether for high-speed lines or flexible batch production, our systems are capable of handling various container types—glass, PET, cans, or jars—with precision and care, supported by intelligent layer preparation and centering units, and automated interlayer removal to guarantee a smooth process.

OCME’s solutions are designed around your facility layout and production goals, with a focus on lean operations, uptime maximization, and operator safety.

With decades of experience, OCME and ROBOPAC have established themselves as leaders in depalletizing technology, offering top-performing machines and tailored engineering support.