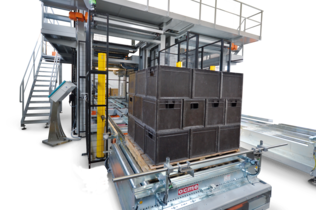

Dorado Depalletiser for bulk products

Dorado is our depalletiser for bulk products. Depending on the chosen model, the product infeed level can be either low with steady pallet (LF) or high with moving pallet (HM).

product benefits

HMI user friendly

High level components complying with the highest safety standards

Possibility to process various types of packs

Inverter-controlled pallet conveyors

Maximum precision and safety during layer transfer phase

Height control by encoder

Operator platform for thepallet unwrapping operations

PROCESSED PRODUCTS

Hdpe containers and jerry cans

Cans

Bottles

overview

Depending on the model chosen, the product infeed can be from low level with fixed pallet (LF) or from high level with mobile pallet (HM). The first phase is the unwrapping of the

pallet.

The first phase is the pallet unwrapping cycle. An operator platform enables the pallet to be reached easily,allowing to carry out any necessary operation in the safest possible conditions. Once unwrapped, the pallet can enter the machine.

The layer is transferred by our gripping head, with self-centring plates (LF) or rotating bars (HM). Layer-pads, frames and top sheets are picked up by the dedicated beam or column-type devices. At last, the packs are extracted and proceed in a single row.

The maximum speed that can be reached by Dorado is 360 layers/hour, in the HM variant (high product infeed level and moving pallet).

For what concerns Dorado with the low product infeed level and steady pallet, it reaches a maximum speed of 150 layers/hour

option & data sheet

Customization according to the customer specifications

Machine version suitable for handling no standard pallets

Side conveyor for gradually outgoing product without pressure

Strap removing device and chopper

tank neck orientation control

case studies

Technologies for Incobrasa and USAID at the service of humanitarian projects

OCME solutions have contributed to the packaging of materials and supplies that USAID has assigned to the United Nations WFP project, which received the Nobel Peace Prize in 2020.

OCME and Robopac innovations for Mahou

Ocme and Robopac are working together to provide the best end-of-line solutions in the beverage sector to a key Spanish customer, Mahou.

Complete “turnkey” solution for Iconic Lubricants

The need to modernise plants and increase their functionality and productivity led Iconic Lubrificantes to look for a single, reliable partner that could guarantee the achievement of the objectives set. OCME was the right answer.

CEPSA, OCME AND ROBOPAC TOGETHER FOR AN EFFICIENT END-OF-LINE IN TERMS OF PRODUCTIVITY AND SUSTAINABILITY

CEPSA turned to Aetna Group for its new lubricating oil packaging line in San Roque (Cadiz): automation, digitisation and attention to energy consumption are aspects that are fully reflected in this new state-of-the-art plant.

GOYA FOODS SPEEDS UP ITS LINES WITH ROBOTICS FROM ROBOPAC AND OCME

The end of line system was designed and implemented using seven technological solutions, among the fastest and most advanced of the entire range of products available within the Group. Let us see which ones: Depalletisers, tray packers, palletisers and wrapping machines from OCME and Robopac.