The company, which is active in more than 40 countries around the world with its food products, required OCME for their oil bottling lines.

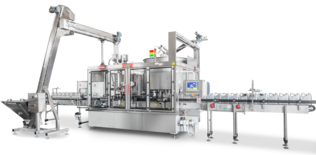

The Parma-based company, which celebrates its 70th anniversary this year, has supplied the entire filling line with two of the group's machines (Libra and Palwrapp) while managing to integrate third-party machines (unscramblers, labellers and conveyors) thanks to its own sales engineering department, which is able to meet the production and space adaptation requirements of the facility.

Furthermore, the Libra R rotary weight filler is a suitable technology for all oil products, as it is able to maintain high precision regardless of product viscosity. Its versatility also allows the handling, filling and sealing of many types of containers (hdpe bottles, pet bottles, glass bottles, cans, etc.) up to a maximum of 10 litres.

Maximum filling accuracy is guaranteed thanks to its highly advanced electronics based on algorithms developed during 20 years of industry use. The machine is MID certified (metrological marking on the quantity of product filled). In addition to its high precision, a rejection system at machine outfeed excludes non-conforming product, ensuring the finished product achieves optimum quality. The speed varies from 6,000 to 40,000 containers per hour.

At the end of the line there is the other main technology installed by the Hellenic company: the Palwrapp 2 Sweep Infeed palletiser. Palwrapp is the only palletiser in the world that palletises and wraps simultaneously, thanks to an integrated wrapping unit in the layer releasing system. This allows the machine to have an extremely compact and flexible footprint. In addition, Palwrapp also represents security, modularity and usability. Infeed products are handled in soft handling mode, with customised creation of the palletising pattern and layer releasing system on pallet, while format change is automatic with zero downtime, guaranteed by the plug and play function.