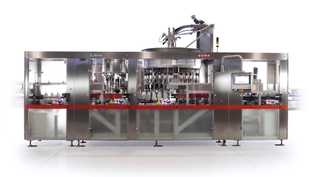

Libra R Rotary weight filler

Our rotary weight filler maintain high precision independent of the temperature and viscosity of the product. Focus on your needs.

Libra R 5

Libra R5 is weight rotary filler solution designed to fill containers from 0,25 to 10 liters such as hdpe bottles, pet bottles, glass bottles, cans and others.

This solution is typical suitable for viscous liquid products such as petrochemical, detergents and edible oil.

Speed range from 6000 to 40000 containers per hour.

Libra R 30

Libra R30 is weight rotary filler solution designed to fill containers from 10 to 30 liters such as pails, jerry cans, cans and others. This solution is typical suitable for petrochemicals products.

Speed range from 600 to 2500 containers per hour.

product benefits

Rejection of containers found outside the weight range

Extremely compact machine

Not affected by air bubbles in the product

PROCESSED PRODUCTS

Pails

Cans

PET bottles with body handling

Glass bottles

HDPE bottles

overview

Libra is our rotary weight filler for viscous liquid, ensuring high performance and efficiency.

This is a body-handling machine designed to handle many types of containers and satisfying the various market requests.

Libra ensures the highest filling accuracy thanks to its highly advanced electronics based on algorithms developed during 20 years of application.

The machine is MID certified (metrological marking on the quantity of filled product).

In addition to its high accuracy, a rejection system at machine outfeed discards non-conforming product, ensuring the finished product to reach an optimum quality.

option & data sheet

Automatic lubrication

Automatic centralized lubrication with pump with programmable cycle from operator interface (only for fixed part of the machine)

Centralised lubrication for capper

Centralised manual lubrication of the capping unit

Complete format changeover

Additional change parts to change container size, it consists of all the necessary parts to handle the container inside the machine

Bottle orienting Control

Control of the bottle orienting by means of sensor

Drop aspiration on nozzles

Suction device with re-use of product in the next container (only for mineral oils).

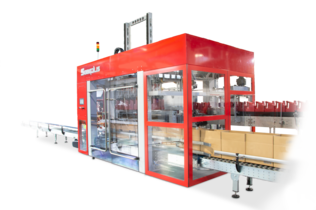

Ejection device

Device to reject containers that are out of tollerance, including ejection conveyor.

Caps elevator

Cap elevator with conveyor

Automatic height adjustment

Automatic height adjustment for filling and capping heads during format changeover.

External tank for nozzles discharge

External tank for nozzles discharge with 100 l capacity, with minimum and maximum level sensors and delivery pump

Metrical certification

Metrical certification of the machine based on MID 2004/22/CE

Motorized nozzle

One of the latest innovations offered by OCME is a fully automatic filling nozzle with opening/closing controlled by a motor and dedicated drive: the shutter positions, speed, acceleration and deceleration can be configured on the HMI according to the handled product/size.

Top cover

Top cover of the machine, not walkable with structure AISI 304 and transparent panels

Parts in contact in AISI 316

Parts in contact with products made in AISI 316

Product tank under pressure

Pressurised product tank within 0.4 bar, for high viscosity products, with electronic pressure adjustment device (using customer's compressed air system)

Spray-ball wash

Automatic system for internal cleaning with 2 sprayballs

Stars, base columns and scales ring

Stars, base columns and scales ring in AISI 304

Trolley for changeover parts

Trolley for changeover parts

brochure

case studies

Lucas Oil a prestigious customer in the United States lube oil industry.

OCME lands a prestigious new customer in the United States lube oil industry. Based in Corona, California, Lucas Oil, has installed the Italian company’s filling and secondary packaging solutions for its range of lubricants and additives for automotive applications.

Technologies for Incobrasa and USAID at the service of humanitarian projects

OCME solutions have contributed to the packaging of materials and supplies that USAID has assigned to the United Nations WFP project, which received the Nobel Peace Prize in 2020.

Complete “turnkey” solution for Iconic Lubricants

The need to modernise plants and increase their functionality and productivity led Iconic Lubrificantes to look for a single, reliable partner that could guarantee the achievement of the objectives set. OCME was the right answer.

CEPSA, OCME AND ROBOPAC TOGETHER FOR AN EFFICIENT END-OF-LINE IN TERMS OF PRODUCTIVITY AND SUSTAINABILITY

CEPSA turned to Aetna Group for its new lubricating oil packaging line in San Roque (Cadiz): automation, digitisation and attention to energy consumption are aspects that are fully reflected in this new state-of-the-art plant.