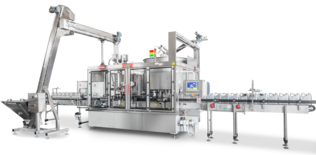

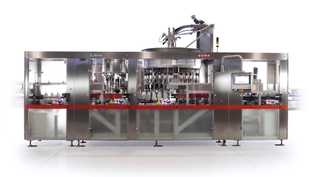

Virgo Rotary Weight Filler for Edible Oil

Virgo is the weight filler for edible oil proposed by OCME, ensuring high performance and efficiency. This machine has been conceptualized in such a way to become a unique combo with the Blow Moulder.

read more

product benefits

Certified and sealed load cells

Rejection of containers found outside the weight range

Not affected by air bubbles in the product

Weight-based filling

PROCESSED PRODUCTS

PET bottles

Glass bottles

overview

Virgo is flexible and can be realized either with neck or body handling, can satisfy all requirements in terms of production speed and type of containers.

Virgo ensures the highest filling accuracy thanks to its highly advanced electronics based on algorithms developed during 20 years of application.

The rejection system at machine outfeed discards non-conforming product.

By the end of the production cycle, all the product inside Virgo is recovered in order to minimize waste.

Virgo is equipped with a control unit dedicated to safety management, ensuring maximum reliability, all including stainless steel and tempered glass perimeter guards . Finally, the machine control and supervisor PC allows to monitor weighing statistics and data logging for each container. This ensures maximum control of production batches.

option & data sheet

Automatic lubrication

Automatic centralized lubrication with pump with programmable cycle from operator interface (only for fixed part of the machine)

Centralised lubrication for capper

Centralised manual lubrication of the capping unit

Complete format changeover

Additional change parts to change container size, it consists of all the necessary parts to handle the container inside the machine

Bottle orienting Control

Control of the bottle orienting by means of sensor

Drop aspiration on nozzles

Suction device with re-use of product in the next container (only for mineral oils).

Ejection device

Device to reject containers that are out of tollerance, including ejection conveyor.

Caps elevator

Cap elevator with conveyor

Automatic height adjustment

Automatic height adjustment for filling and capping heads during format changeover.

External tank for nozzles discharge

External tank for nozzles discharge with 100 l capacity, with minimum and maximum level sensors and delivery pump

Metrical certification

Metrical certification of the machine based on MID 2004/22/CE

Motorized nozzle

One of the latest innovations offered by OCME is a fully automatic filling nozzle with opening/closing controlled by a motor and dedicated drive: the shutter positions, speed, acceleration and deceleration can be configured on the HMI according to the handled product/size.

Top cover

Top cover of the machine, not walkable with structure AISI 304 and transparent panels

Product tank under pressure

Pressurised product tank within 0.4 bar, for high viscosity products, with electronic pressure adjustment device (using customer's compressed air system)

Stars, base columns and scales ring

Stars, base columns and scales ring in AISI 304

Nitrogen insertion

From the bottom filling nozzle with pipe inside to let inside a predetermined amount of nitrogen. Production speed is slightly slower with this device.