Founded in 1886 in Fara San Martino (Chieti), De Cecco has earned the trust of consumers all over the world, thanks to constant investment in quality and tradition.

Today the company is synonymous with the excellence of Made in Italy and it operates several sites globally as a leader in the food industry, not only for the quality of its products but also for the technological level of its processes.

In the production area of the Ortona plant, De Cecco turned to OCME with the request to maximise the efficiency of the palletising process while at the same time guaranteeing great flexibility (qualities which are widely desired in the food sector), in order to handle on demand line requirements.

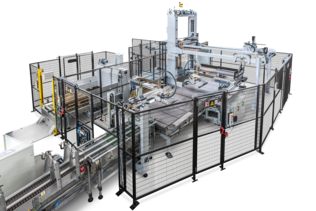

After careful evaluation, OCME opted for the Perseus HM N system, a high-level infeed palletiser capable of easily handling products from three different packaging lines and three codes without the need to change format, and with the advantage of handling different weights, sizes and heights.

In an increasingly dynamic and changing market landscape, this solution, with its exceptional built-in flexibility, allows De Cecco to adapt quickly and seamlessly to developments without compromising its production rate.

The installation helps to save space within the industrial layout and optimise the workflow as a result.

The collaboration between De Cecco and OCME represents an excellent synergy between tradition and innovation in the food industry. Through state-of-the-art solutions such as the Perseus HM N, De Cecco continues to maintain its leading position in the industry, guaranteeing the highest quality and efficiency at every stage of the production process.