Thanks to intensive research and development supported by two in-house laboratories, around 50 new products per year are launched on the market and continuous improvements are made to existing production. The name Sano therefore conjures up excellence in a wide selection of home product categories - laundry products, dishwashing detergents, disinfectants, air fresheners, bathroom cleaners and insecticides - as well as a wide range of personal care items.

In this rich production environment, Sano international stands out as a key player in the tissue industry, a segment in which Aetna Group is a major supplier for end-of-line stages. This combination of excellence is housed in the main factory in Hod Hasharon, Israel.

This is where the know-how of OCME and Robopac meet for two flexible, high-performance end-of-line systems.

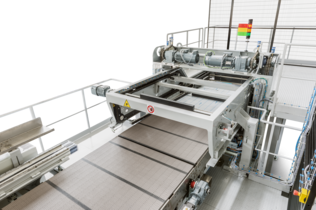

To handle the palletising phase, the Israeli company chose a robotic solution with OCME's Pegasus layer gripper, accurately synchronised with a divider system to form the layer for the packaging from the production line.

The island is completed with a compact pallet transport system to feed the rotary arm wrapping machine Helix HS30, which has been guaranteeing excellent results in terms of wrapping quality and performance in the factory for 20 years. The wrapping machine produced by Robopac is equipped with a TOP device to ensure complete 5-sided protection of the customer's packaging.

Two solutions that are still fully operational after almost twenty years, an undeniable sign of the quality and reliability that the Group is able to guarantee.

Still in the palletising area, OCME also supplied a conventional palletising system with the Orion model with product infeed from above: a high-performance, fully automatic and 100% safe solution. This is one of the fastest palletisation models on the market.

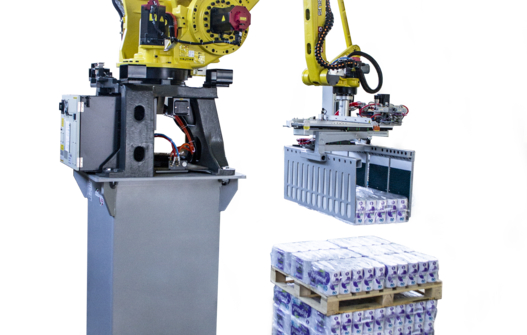

Product infeed and layer formation are performed by a handling robot with a gripping head, which allows optimising the position pattern of the packages coming from the line to improve the layer release.

Thanks to this robotic layer-forming solution, the Mizar model can handle all major product packaging such as SKUs, bundles or displays with the utmost care.

The flexibility to handle different formats and packaging is supported in real time by the Program maker, a digital tool developed by OCME that facilitates the customer to optimise and change palletising patterns according to production needs.

With regard to the packaging of palletised loads, the line was equipped with automatic rotary arm wrapping machines produced by Robopac: a Helix 3 EVO with the TOP covering device and film cutting and sealing system without contact with the product, and a Helix HS30, also with TOP device, which has been guaranteeing excellent results in terms of quality and wrapping performance for 20 years. These wrapping machines belong to technologies that are particularly suitable for use in product sectors where high production rates are required and for light, easily deformable and unstable products such as tissue products.