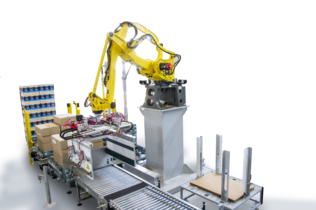

Pegasus Layer Robotic palletizer with layer gripper

We offer a wide range of applications for their robotic gripping heads. Each solution is specifically designed to handle the type of product requested in the most efficient way.

Jalouse gripper head

Fully automatic jalouse gripper head that can handle multi-code lines.

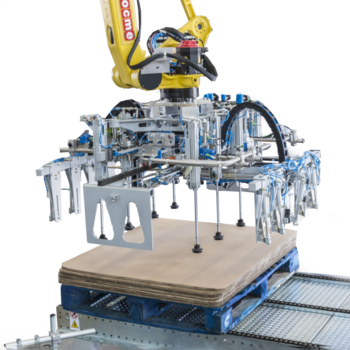

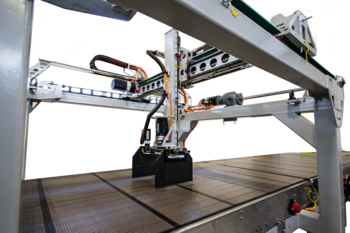

Pegasus Layer

Pegasus with layer gripper with lower retaining forks in carbon is the version with the highest performance among the palletisers offered by OCME, with its 10.5 layers/minute.

Thanks to the new forks in carbon, the product is released on the pallet from a gap of a few millimeters, eliminating the risk of damaging the product.

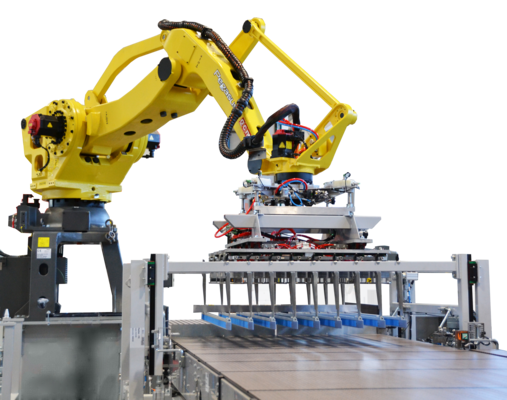

Layer gripper for bulk container

Ideal solution for a green pakaging thanks to the possibility to manage loose products in trays during the palletizing phase, directly creating tertiary packaging solutions ready to be displayed on the point of sale.

product benefits

HMI user friendly

High versatile and flexible

EXTREMELY STURDY MACHINE

HIGH SPEED

SAFETY FIRST

POSSIBILITY TO USE FRAGILE CONTAINERS, PRESERVING THEIR INTEGRITY

Processed Products

Tissue products

Cartons

Bundle

Bulk containers

overview

The configuration of the robotic island can be customised according to the type of container to be processed and the

speed of the line.

Before the palletising phase, the layer is created using the Mizar layer forming system.

OCME gripping heads can be motorised or pneumatic, with plates without lower layer support (OCME patent) or with support (apron or forks).

option & data sheet

AUTOMATIC FEEDING SYSTEM FOR LAYER-PADS

The purpose of the operation is to insert the cardboard layer-pad in the correct position in the shortest possible time and without hindering the movement of other elements such as, for example, the robot palletiser arm.

The system guarantees great autonomy for feeding the layer-pad and is suitable for both traditional and robotic palletizing installations.

-

Pallet with stacked interlayer pads is positioned on the upper conveyor

-

The scissor lift progressively raises the stack to the correct gripping position

-

Column type or robotic type interacting gripper puts the pads between the layers during the palletising phases

The scissor lift descends to the lower level of the conveyor to eject the pallet at the end of the pads

-

Self-centring motorised side guides for intermediate pads

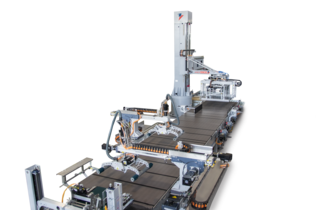

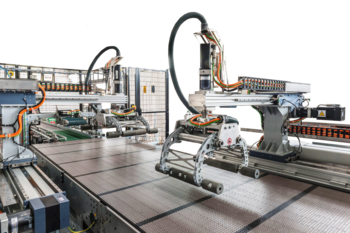

MIZAR Layer Forming system

The phase of pack rotating and layer forming has the purpose of arranging the packs according to a specific configuration required for the following phase of palletising in order to guarantee the highest stability of the pallet and the optimal number of products / layer.

Manipulators are designed to provide a high performance infeed to all types of palletisers: 90°, in-line and with robots.

The task of the manipulator is to translate and/or rotate the product to form and compact the layer, minimizing shocks or stress, especially for fragile or unstable products.

The layer forming system using manipulators is flexible and extremely precise, it can handle any type of pack, even the most delicate.

There are three variants of manipulators: Cartesian, robot or gantry manipulators.

All versions use brushless motorised gripping heads to guarantee maximum precision and optimal control of the clamping force.

The forming belt is driven by brushless motors to ensure maximum stability of the packs.

A significant differentiating element of the manipulators is the accessibility to each area of the system: in case of need, the operator can reach any point for any intervention in maximum safety.

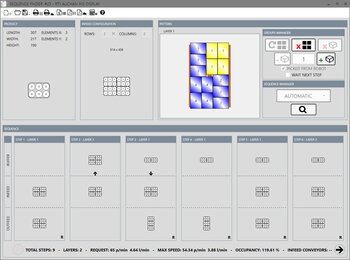

Program maker

Software that simplifies the creation of palletising pattern thanks to a mainly graphic structure.

Thanks to the engineering that develops the software for our products and a dedicated research and development department, we can offer an interface that allows our customer to create and modify the palletising programs.

This very intuitive system allows you to check the picking and depositing settings through previews generated on the screen that display the result of the settings before the machine is started.

Starting from two simple information, pack size and pallet type, the system generates a series of palletising schemes that are the starting point for the choice of the desired sequence.

The 3-D previews that accompany the entered settings facilitate the definition of the work to be done and allow you to make changes and verify the result in real time.

Further, the programming interface navigation is sequential, so you will need to complete all the steps to get a new palletising program.

Gripper head for unstable products

We have a wide range of applications for their robotic gripping heads.

Each solution is specifically designed to handle the type of product requested in the most efficient way.

EMPTY PALLET INFEED SYSTEM

The empty pallet infeed system supplies the palletiser with empty pallets, so that this task needs not be carried out manually.

The system is designed to guarantee maximum flexibility in terms of variations in pallet size. flexibility in terms of variations in pallet size.

The system may be used with 4 forks instead of 2, so as to be able to use half-pallets (also called “demi-pallets”).

Mizar Advance - Layer forming systems

Gantry layer forming system designed by OCME to enhance performance in layer forming processes to any palletiziers. Sustable for several products for food and beverage sectors.

brochure

case studies

OCME and Robopac innovations for Mahou

Ocme and Robopac are working together to provide the best end-of-line solutions in the beverage sector to a key Spanish customer, Mahou.

Jafora entrusts OCME with palletizing and wrapping

Jafora is an important producer of soft drinks and juices from Israel, recognized worldwide for its technical expertise and its excellence in the research of the latest technological solutions for its plants.

Complete end-of-line for the tissue industry installed at FUTURA LINE

The customer's request was clear: to propose and design an automatic end-of-line system and logistic management of products on pallets, starting from a green field. OCME has been able to carry out this project by automating all the needs of the Italian Futura Line Group.

SANO INTERNATIONAL AND AETNA GROUP: TWO LEADERS IN THE TISSUE INDUSTRY MEET

Sano international is an Israeli company with a long and successful history behind it, which today manufactures and markets over 500 Home & Personal Care products worldwide. Innovation, sustainability and quality are the core of the company's business, which is conducted in three production plants in Israel and one in Romania.

Aetna Group and Mahou San Miguel: quality and flexibility are at the core of a trusted partnership

Driven by a constant pursuit of innovation in production processes, Mahou San Miguel - Spain’s leading beer producer - remains committed to using Aetna Group’s advanced packaging technologies to further enhance the efficiency of its glass and can packaging lines.