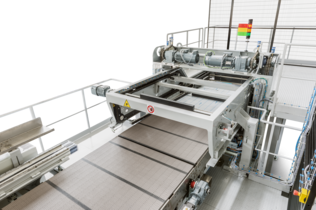

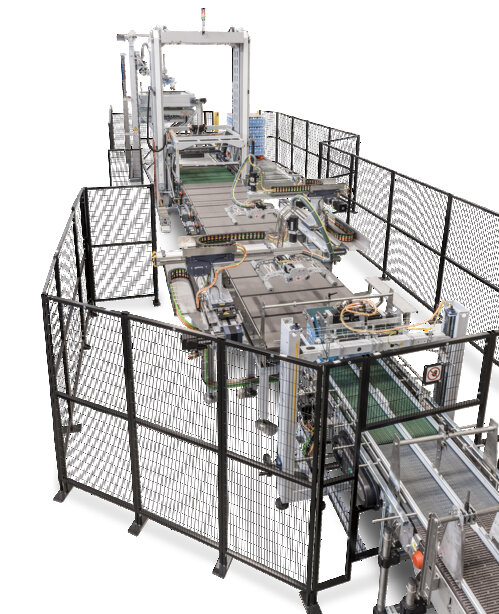

Orion Advance Conventional In-line palletizer

The faster conventional palletizer: a low level infeed palletiser with double sliding table ensuring high performance with reduced dimensions.

product benefits

High accessibility

thanks to the low infeed is not necessary to use platforms or elevators

HMI user friendly

High level components complying with highest safety standards

Machine fully operated by brushless motors

Possibility of processing various types of packs

Fully automatic

PROCESSED PRODUCTS

Tissue products

Package with bundle

Cartons

overview

The high efficiency palletiser in line with your needs.

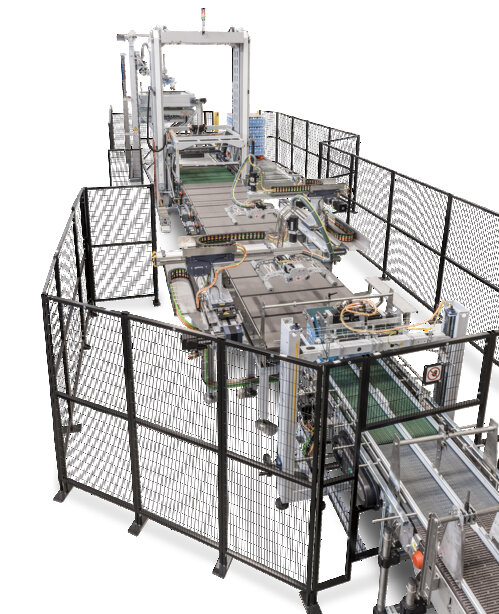

Orion Advance is a high speed, inline palletizer that includes a combination of standard features that makes ideal for gentle handling of current and future package types and sizes.

Once the layer has been formed by the forming unit, the product will be transferred towards the machine and placed onto the pallet, with the possibility to insert flat pads.

Solution created for the beverage sector but applicable to all those sectors where it is necessary to combine accessibility, compactness and speed.

Orion Advance, with low level infeed and double sliding table, reaches a maximum speed of 570 layers/hour.

All Orion models are integrated with an automatic system forming the layer.

option & data sheet

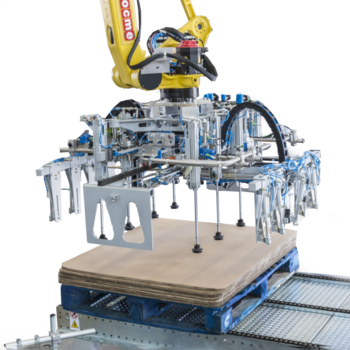

AUTOMATIC FEEDING SYSTEM FOR LAYER-PADS

The purpose of the operation is to insert the cardboard layer-pad in the correct position in the shortest possible time and without hindering the movement of other elements such as, for example, the robot palletiser arm.

The system guarantees great autonomy for feeding the layer-pad and is suitable for both traditional and robotic palletizing installations.

-

Pallet with stacked interlayer pads is positioned on the upper conveyor

-

The scissor lift progressively raises the stack to the correct gripping position

-

Column type or robotic type interacting gripper puts the pads between the layers during the palletising phases

The scissor lift descends to the lower level of the conveyor to eject the pallet at the end of the pads

-

Self-centring motorised side guides for intermediate pads

EMPTY PALLET INFEED SYSTEM

The empty pallet infeed system supplies the palletiser with empty pallets, so that this task needs not be carried out manually.

The system is designed to guarantee maximum flexibility in terms of variations in pallet size. flexibility in terms of variations in pallet size.

The system may be used with 4 forks instead of 2, so as to be able to use half-pallets (also called “demi-pallets”).

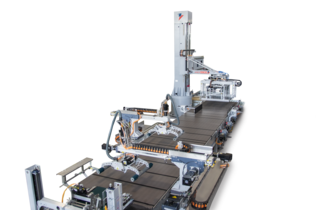

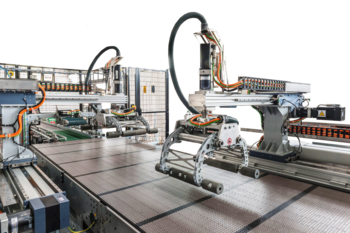

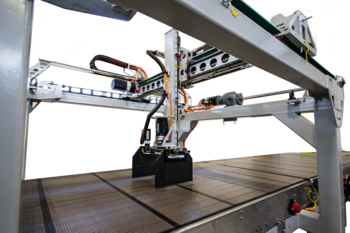

MIZAR Layer Forming system

The phase of pack rotating and layer forming has the purpose of arranging the packs according to a specific configuration required for the following phase of palletising in order to guarantee the highest stability of the pallet and the optimal number of products / layer.

Manipulators are designed to provide a high performance infeed to all types of palletisers: 90°, in-line and with robots.

The task of the manipulator is to translate and/or rotate the product to form and compact the layer, minimizing shocks or stress, especially for fragile or unstable products.

The layer forming system using manipulators is flexible and extremely precise, it can handle any type of pack, even the most delicate.

There are three variants of manipulators: Cartesian, robot or gantry manipulators.

All versions use brushless motorised gripping heads to guarantee maximum precision and optimal control of the clamping force.

The forming belt is driven by brushless motors to ensure maximum stability of the packs.

A significant differentiating element of the manipulators is the accessibility to each area of the system: in case of need, the operator can reach any point for any intervention in maximum safety.

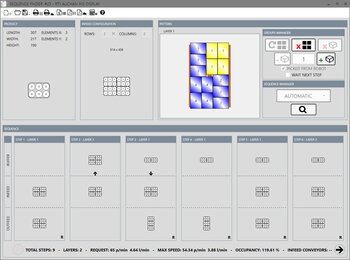

Program maker

Software that simplifies the creation of palletising pattern thanks to a mainly graphic structure.

Thanks to the engineering that develops the software for our products and a dedicated research and development department, we can offer an interface that allows our customer to create and modify the palletising programs.

This very intuitive system allows you to check the picking and depositing settings through previews generated on the screen that display the result of the settings before the machine is started.

Starting from two simple information, pack size and pallet type, the system generates a series of palletising schemes that are the starting point for the choice of the desired sequence.

The 3-D previews that accompany the entered settings facilitate the definition of the work to be done and allow you to make changes and verify the result in real time.

Further, the programming interface navigation is sequential, so you will need to complete all the steps to get a new palletising program.

Mizar Advance - Layer forming systems

Gantry layer forming system designed by OCME to enhance performance in layer forming processes to any palletiziers. Sustable for several products for food and beverage sectors.

brochure

related products

case studies

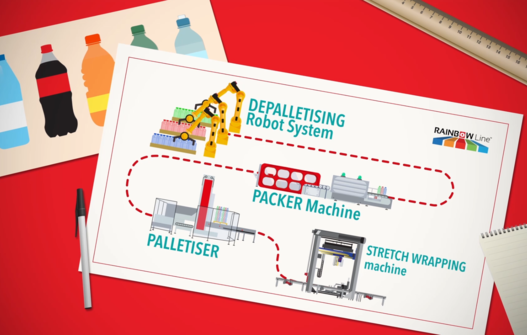

Multiflavour Line Rainbow

Designed around specific customer's need, OCME can offer a integrated systems that allows to palletize multi flavour bottles with different multiflavour configuration on a single tray to meet customer's aim.

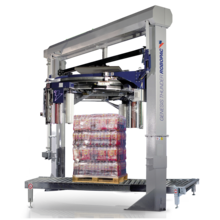

GOYA FOODS SPEEDS UP ITS LINES WITH ROBOTICS FROM ROBOPAC AND OCME

The end of line system was designed and implemented using seven technological solutions, among the fastest and most advanced of the entire range of products available within the Group. Let us see which ones: Depalletisers, tray packers, palletisers and wrapping machines from OCME and Robopac.