In a new step towards sustainable packaging and technological evolution, OCME has worked together with suppliers ExxonMobil Chemical and RKW Group to develop a new type of high quality film made with virgin polyethylene from ExxonMobil and post-consumer recycled PE content.

Responding to brand owner commitments, consumer feedback and regulatory requirements, OCME collaborated with ExxonMobil to develop a collation shrink film that includes virgin polyethylene (PE) and 50% Post-Consumer Recycled content (PCR) with same performance and same processability at same thickness.

The collation shrink film formula is based on Enable™ 4002, an ExxonMobil high-performance PE polymer, that when combined with PCR PE (present in shrink films), acts as a performance booster.

These polymers provide a unique value thanks to the combination of high mechanical properties, excellent optics and shrink performance.

RKW Group a well-known private company based in Germany and recognized worldwide as an important producer of high-quality films created printed film reels that offer the same physical-mechanical characteristics and processability of traditional full virgin solution, with sustainability benefits.

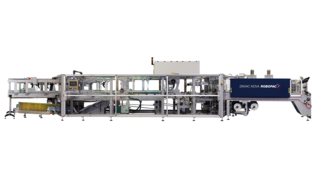

The final product can be used both on OCME machines and on all Robopac packing machines.

The solution reflects the dedication of a collaborative group focused on innovation while striving to comply with environmental regulations and safeguard the planet.