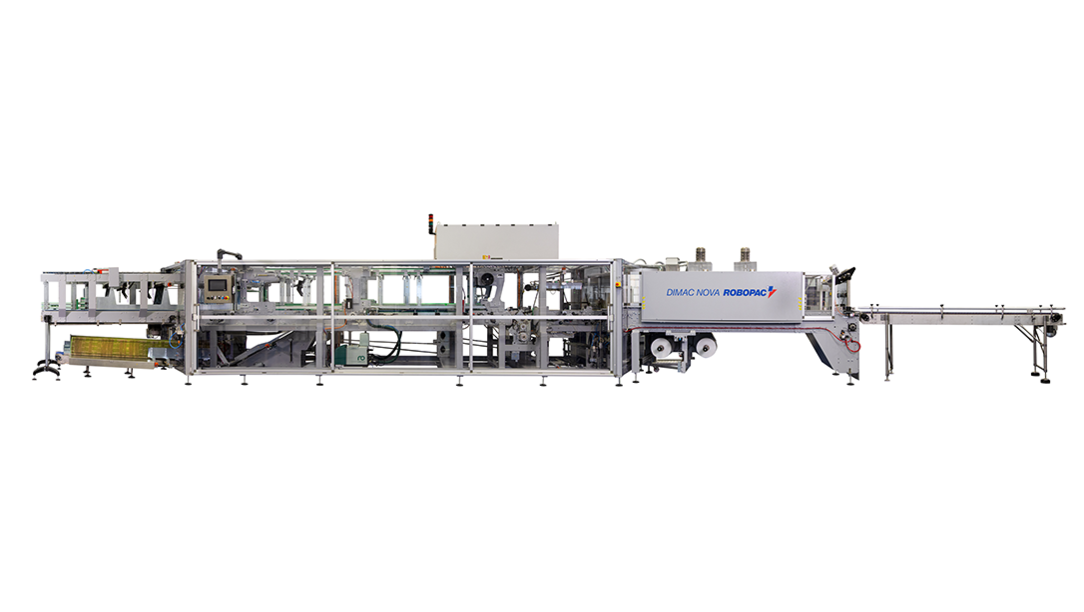

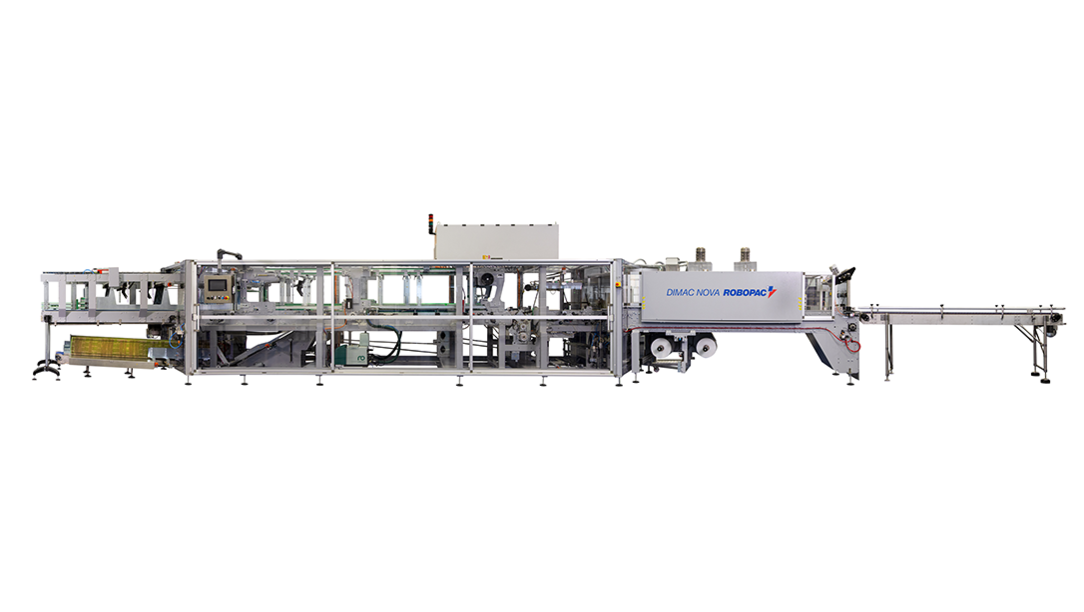

DIMAC NOVA 30/40 Shrink-wrappers for medium-speed productions

Dimac Nova is the range of shrink-wrapping and tray forming machines developed by Robopac, designed to have maximum flexibility and ease of use & maintenance for operators.

PACKAGING MODELS

DIMAC NOVA NOVA 30/40

Depending on the set-up, this series can realise all the classic secondary packaging solutions with film and carton tray.

|

|

|

|

|

|

|||

|

packs with film only |

packs with flat pad and film |

packs with tray and film |

packs with tray only |

product benefits

flexible

Maximum flexibility

easy

Ease of use and maintenance

modular design

Designed in an extremely modular way

possible options

Possibility of adding options

STANDARD EQUIPMENTS

Wide machine frame

Full length sliding doors for complete visibility and accessibility. 2/3 of the machine length open. The electrical cabinet is integrated on top of the machine frame.

Touch screen display

Wide and user-friendly touch screen display. It gives operators the possibility of managing all machine parameters and keeping all its functions under control.

Led lighting

Led lighting of the working area to facilitate cleaning and maintenance operations.

Film unit

Easy accessibility to the film unit thanks to the swinging conveyor. In case of film vacuum table, the accessibility to the film group is granted by an extractable unit.

overview

This machine family is designed in an extremely modular way, both in terms of packaging types and possibility of adding options, that can eventually be added in the future in an absolutely scalable way.

Dimac Nova 30T

option & data sheet

High Performance Shrink Tunnel

The tunnel is equipped with external regulation to optimise air flow according to the different configurations. Conveyor voltage is maintained constant by a counterweight in the final part of the tunnel. It is possible to have the H.P. standard shrink-tunnel for normal tasks and the H.P. plus for enhanched tasks.

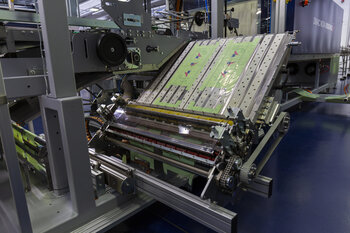

REMOVABLE FILM UNIT

The system offers easy access to the film unit, for quick and efficient maintenance. This application is particularly suited for liquid product sectors, such as dairy and beverage, where the primary packaging may break, possibly soiling the film.

Automatic reel change

The system seals and cuts the film in a fully-automated fashion without any operator intervention, this option makes it possible to continue without stopping film unwinding and the production cycle. The reel configuration is set up by the operator, through simple manual procedures.

Automatic format change

Format change operations are carried out simply from the operator panel. The switch to the new format is carried out electronically through brushless motors.

Double layer stacker unit

This is a fully scalable option that allow you to stack two layers of product, the unit can be configured differently based on the type of product or the packaging solution.

Easy film

External film group for reel loading that grants better access for format change operations and reel sealing means excellent man-machine interaction. The external reels option also offers automatic reel-change.

Standard Technical Features

|

Total length |

mm |

F 6765 - P 6765 - T 8444 |

|

Machine width (+ electric panel) |

mm |

1563 |

|

Worktop height |

Kw |

1050 - 1150 |

|

Standard Electrical Characteristics (*) |

||

|

Total power |

Kw |

F 42 - P 42 - T 42 |

|

Standard Pneumatic Characteristics (*) |

||

|

Air consumption |

Nl/min |

20 - 100 |

|

Air pressure |

BAR |

6 |

|

(*) Values are purely theoretical. We recommend contacting Dimac to assess the specific values for each project according to the products and materials used. |

|

|

brochure

case studies

COLLABORATION WITH EXXONMOBIL Chemical AND RKW TO DEVELOP NEW PRINTED FILM CREATED WITH RECYCLED POLYMERS

In a new step towards sustainable packaging and technological evolution, OCME has worked together with suppliers ExxonMobil Chemical and RKW Group to develop a new type of high quality film made with virgin polyethylene from ExxonMobil and post-consumer recycled PE content.