Value Palletizer Smallest Footprint In Market

Robotic palletizing has become an increasingly accepted alternative to traditional layer palletizing, but the solution is not without challenges. Typical generic robotic palletizers experiences limits on products that can be handled, performance issues with deviations in product uniformity, special training to handle complexities of robot programming, large footprint, custom integration, and the expense of support. All these shortcomings are eliminated with the robotic palletizer.

close

key features

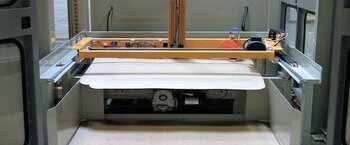

Smallest footprint available for automatic palletizing

89” wide by 129” long

Modular Design

Configurable to fit in nearly any space. Three load exit or entrance sides are available for standard manual pallet jack handling of loads.

EasyStack® Software

TopTier palletizers can build any pallet pattern, with up to 99 patterns stored and instantly accessible. End users can easily create new patterns using the HMI touch screen common to both conventional and robotic models.

Allen Bradley controls

Higher speed configurations PLC’s and VFD’s

overview

SAFETY FIRST

TopTier’s robotic palletizers are a fully integrated purpose built palletizing solution, as opposed to an assembly of a robot, guarding, end of arm tooling with separate controls. Each frame element is an integral part of a Category 3 PLd controlled entrance safety enclosure. 100% bottom supporting row build and pick and place systems are integrated into the frame structure, including Allen Bradley controls. Safety is not an accessory. The integrated safety system with controlled entrance protocols prevent hazard until the safety system affirms safe conditions exist.

BOTTOM SUPPORT

Limitations of nearly all robotic pick to pallet solutions are products being palletized must be suitable for vacuum top picking with rate potential limited due to single case pick to pallet cycles. TopTier’s robotic models have overcome such limitations combining patented row building technology with an Allen Bradley servo-controlled row pick and place solution where product is 100% bottom supported until deposited on load. The resulting solution achieves higher rates, can handle nearly any product, and is delivered 100% assembled ready for work in the smallest and most configurable footprint available.

option & data sheet

Load Handling

Automated load exit is available with pallet conveyor of any length required for load accumulation.

Pallet Handling

Empty pallet handling consists of a pallet dispenser and systems to position a pallet at the load build. Pallets used by in industry vary in quality, height and design. Empty pallets are difficult to reliably transport due to inconsistencies in the pallet bottom. Pallet handling system positively position and square empty pallets using pusher systems and the pallet dispenser is a universal lift and separate design using forks to reliably support the pallet stack.

Sheets handling

TopTier offers comprehensive sheet handling capabilities. Freezer separator sheets that facilitate air flow are handled. Sheet insertion equipment is used to place an empty pallet onto a half load allowing double stack loads.

Features

Pallet liners are inserted with a horizontally travelling vacuum pick and place device

Tie sheets, freezer sheets, slip sheets, and top caps are inserted with a vertically and horizontally travelling vacuum pick and place device capable of placing a sheet at any level of the load

Sheets inserted at load build position for unitized loads

Tie sheet inserters can be equipped with up to three pick positions allowing separate sheet styles

Low Infeed: Sheets are loaded into a 18" capacity drawer and safely loaded during palletizer operations

High Infeed: Sheet inserter mounted above or at mezzanine level. The mezzanine level device is manual loaded with up to 18" of sheets with one or two bins available. Bins may be loaded at ground level and positioned with a forklift. Optional lift device is available to raise sheet stack to the upper level position.

Sheet bin loading with no interruption of operations

Sheet size less than 60" in either dimension including 2, 3 or 4 tab models

Capacity of 18" of sheets

| Rates | 10-12 cases per minute |

| Products | Every product type, including case, bag, tray, trayless, open top, lidded, overwrapped or unwrapped, bundles, nested, display pack, totes, and more |

| Minimum Case Dimension | 5" |

| Maximum Case Dimension | 24" |

| Maximum Case Height | 18" |

| Maximum Case Weight | 200lbs |

| Minimum Layer Dimension | 38" |

| Maximum Layer Dimension | 50" |

| Standard Load Height | 84" |

| Footprint | 89" x 129" |