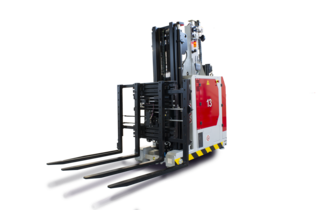

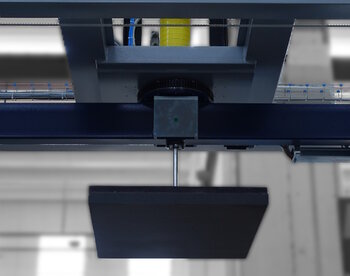

HELIX 4/2 Fully automatic double rotary arm wrapper

Automatic stretch wrapping machine with double rotating arm to meet the requirements of load stabilization on pallets, in cases of high hourly output

product benefits

S-PATTERN

Lower neckdown, maximum savings

LOW TCO

Reduced total operative costs

MODULAR DESIGN

Prepared for quick upgrades setup

QUICK AND FLEXIBLE SETUP

Quick and easy replacement of most components

FAST INSTALLATION

Pre-assembled, ready-to-go for fast installation & ramp-up

HEAVY DUTY CONSTRUCTION

High operational reliability and durability under the most severe conditions of use

STANDARD EQUIPMENTS

SCSP - FIXED PRE-STRETCH CARRIAGE

Single motorization allows pre-stretch at fixed values up to 300% and apply up to 12 containment force values on the pallet. Force to load adjustment through load cell. Stadard version 500 mm/20" film height; available 750 mm/30" as option

SPRING CLAMP

Film clamping cutting and sealing system which occurs without contact with the product.

overview

The wrapping times are virtually halved with respect to the single arm wrappers, thanks to the mirror feature of the machine with a double arm on which the pre-stretch carriages and double film clamping and cutting system are installed.

HELIX 4/2 FULLY AUTOMATIC DOUBLE ROTARY ARM WRAPPER FOR VERY HIGH SPEED

option & data sheet

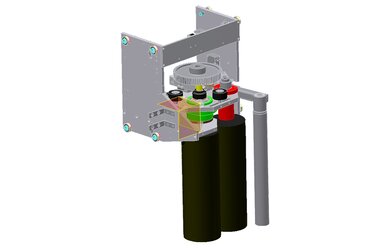

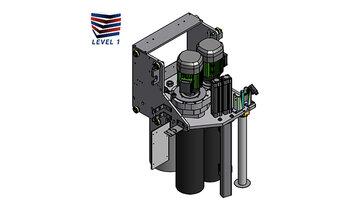

SCSP/2B - CUBE TECHNOLOGY L.1 - VARIABLE PRE-STRETCH CARRIAGE

Pre-stretch carriage with double independent motorization, which allows to set pre-stretch ratio of the film from the control panel, with a 100% - 400% range and control system through inverter.

The standard carriage is equipped with a 500 mm/20" film reel height; optional carriage can be equipped with a 750 mm/30" film reel height.

Containment force with reactive software system based on CUBE TECHNOLOGYTM Level 1, using a load cell.

Pre-stretch and containment force can be set up to 12 different levels inside each wrapping program, with simple adjustments on the HMI

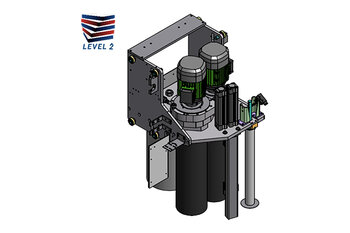

SCSP/2_P - CUBE TECHNOLOGY L.2 - VARIABLE PRE-STRETCH CARRIAGE

It is possible to apply up to 12 containment force values on the pallet.

VERTICAL PRESSURE PLATEN

Device for pallet retaining system that apply a vertical force on the pallet during the wrapping cycle, to keep it more stable during wrapping operations.

Used with particularly unstable loads and the upper covering systems (Top Inside/Top Outside).

Available in versions with mechanical movement by means of pantograph system or pneumatic drive.

TOP OUTSIDE COVER DEVICE

Automatic system for covering the upper surface of the pallet against dust.

It's an independent structure placed outside the machine, normally installed on the conveyor before wrapper position.

The top of the pallet is covered with the pallet in motion.

The device has electrical system integrated with the wrapping machine.

An electrical crane system (optional) is fixed on the top structure for easier reel replacement.

ROPING DEVICE

Optional system to reduce the width of the film to a "rope" and ensure a more effective stabilisation of the load.

Available in 3 versions:

ROPING FROM BOTTOM

Reduce the film bandwidth from the bottom, creating a small rope that is applied at the level of wood axis of the pallet, while the remain part of film not roped is applied on product.

ROPING FROM TOP

Reduce the film bandwidth from top to bottom, to create a complete rope that is normally applied at the level of wood axis of the pallet.

The pallet is wrapped from the bottom up to its top with open band film. The film band is then narrowed from the top along its entire length to create a "rope" and applying the cord in a spiral down to the bottom. The final part of the cycle is carried out with open film.

ATTENTION: this operation involves the "cord" being placed on the product. If the product or its packaging is delicate they could be damaged.

ROPING WITH DOUBLE MOVEMENT

The cycle consists in wrapping the pallet from the bottom up to its top with film in open band to then narrow it from the top downwards forming a double "rope". The final part of the cycle is carried out with open film. The narrowing movements of the film band can be independent or synchronised with each other.

ATTENTION: this operation involves the "cord" being placed on the product. If the product or its packaging is delicate they could be damaged.

CENTER MACHINE PALLET LIFTER

Device to lift up the pallet in order to allow the wrapping of the wooden pallet.

It is normally used in combination with roping device to guarantee the maximum stability of the load

Available with pneumatic or hydraulic drive.

It is located under the central machine conveyor.

VCA - CORNER APPLICATOR

Automatic corner applicator device for the protection of the pallet corners.

It consists of vertical storages combined with vaccum grippers and moving hands.

Thanks to a special control system (ROBOPAC patent) the vacuum grippers are able to "locate" in a fully automatic way the corners of the pallet, without any manual setting or adjustment.

RCONNECT

Device for controlling, collecting, processing and filing large amounts of data from installed machines. Through a dedicated access-controlled portal, accessible from PCs or any portable device, you can connect to all machines equipped with the Rconnect system and monitor their performance 24/7.

- Monitor your performance

- Improve your efficiency

- Detect and inspect your line failures

- Remote assistance in private connection without need of company LAN

SLIPSHEET FOLDING DEVICE

Device to allow the wrapping of lower flaps on slip-sheets with or without wooden pallet.

| Pallet dimensions min - max | mm |

600x800 - 1000x1350 |

inches | 24x32 - 40x53 | |

|

Max pallet dimensions XL Version |

mm | 2000x2000 | inches | 80x80 | |

| Maximum pallet height | mm |

2000 |

inches | 80 |

| Standard power supply voltage and frequency | V - Hz |

400-415 ± 5% - 50 ± 1% |

| Optional power supply voltage and frequency | V - Hz |

380-480 ± 5% - 60 ± 1% |

| Compressed air pressure | Bar |

6 ± 1 |

| Film reel height | mm |

500 |

inches | 20 | |

| Max reel diameter | mm |

250 |

inches | 10 | |

|

Optional film reel height |

mm | 750 | inches | 30 |

brochure

related products

HELIX MAX

Fully automatic rotating arm with two reels

- ROTATING ARM

- HIGH SPEED

GENESIS FUTURA 40

Fully automatic rotary ring wrapper

- ROTATING RING

- MEDIUM SPEED