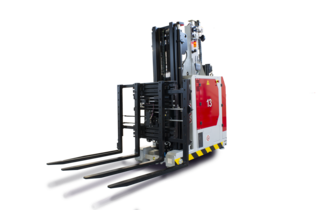

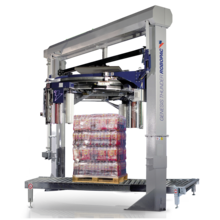

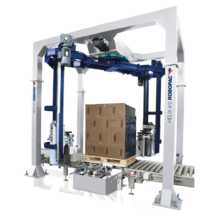

GENESIS THUNDER HS Fully automatic rotary ring wrapper

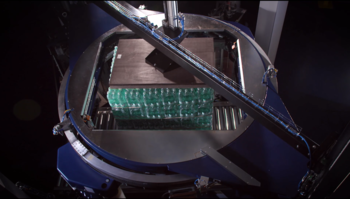

Genesis Thunder HS is a fully automatic rotating ring machine engineered for high-speed pallet wrapping. This solution is ideal for end-of-line packaging lines requiring top performance, precision and film efficiency.

product benefits

S-PATTERN

Lower neckdown, maximum savings

LOW TCO

Reduced total operative costs

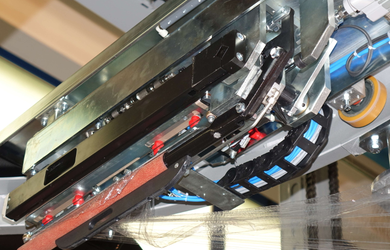

DIRECT-DRIVE PRE-STRETCH ROLLERS

Servo controlled direct-drive motors for full control of pre-stretch and containment force

HYGENIC DESIGN

Glattes und sauberes Design für leichte Reinigung

DYNAMIC PARACHUTE

Double redundant and continuous locking mechanism for maximum operator safety

MODULAR DESIGN

Prepared for quick upgrades setup

QUICK AND FLEXIBLE SETUP

Quick and easy replacement of most components

WRAPPING FLEXIBILITY

Possibility to start and finish wrapping cycle at any position on the load

STANDARD EQUIPMENTS

BGS - FIXED PRE-STRETCH CARRIAGES

Servo controlled with external direct-drive motorization to pre-stretch the film at fixed values up to 350%. Force to load is controlled by a REACTIVE analogic system.

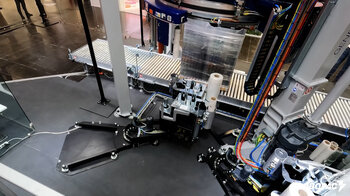

FUTURA CLAMP

Pneumatically driven clamp unit with hot wire film cutting which incorporates also the device for final sealing of the film tail on the contrast.

overview

Genesis Thunder HS, born to set higher standards

· HI-RESISTANCE MONOBLOCK ALUMINIUM RING

· SERVO CONTROLLED DIRECT-DRIVE PRE-STRETCH MOTORS

· HYGENIC & ERGONOMIC DESIGN

· NOISELESS OPERATION WITH EXTREMELY REDUCED MAINTENANCE

· ENGINEERED TO REDUCE MAINTENANCE & INTERVENTIONS

· AUTOMATIC DYNAMIC PARACHUTE

· MAXIMUM FLEXIBILITY WITH ALL THE PALLET SIZES

4 columns version available as option

GENESIS THUNDER HS BORN TO SET HIGHER STANDARDS

option & data sheet

BGS_P - FIXED PRE-STRETCH CARRIAGE WITH PROACTIVE SYSTEM

Possibility to pre-stretch the film in fixed way apply up to 12 containment force values on the load.

The adjustment of the containment force on the pallet is controlled by a PROACTIVE system using a perimeter tension.

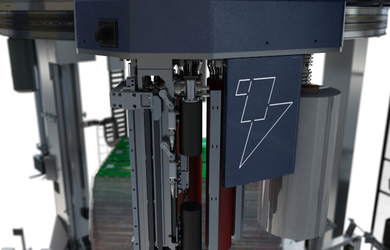

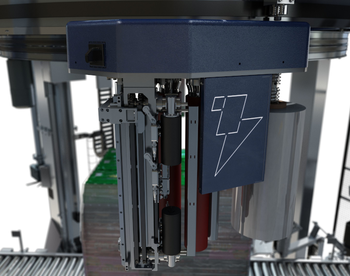

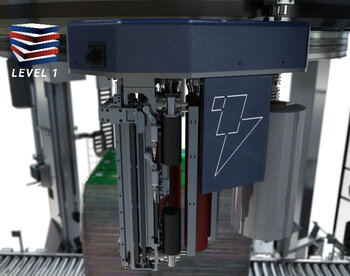

BVS - CUBE TECHNOLOGY L.1 - VARIABLE PRE-STRETCH CARRIAGE

Pre-stretch carriage with rollers controlled by two external direct-drive servo-motors.

Possibility to pre-stretch the film in variable way, in continuous and adjustable on HMI and apply up to 12 containment force values on the load.

The standard carriage is equipped with a 500/20" mm film reel height; optional carriage can be equipped with a 750/30" mm film reel height.

The adjustment of the containment force on the pallet is controlled by a REACTIVE system based on the CUBE TECHNOLOGYTM Level 1.

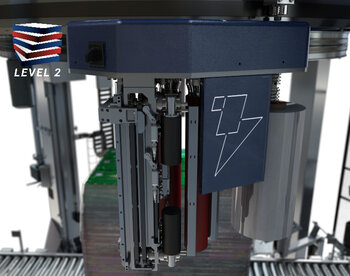

BVS_P - CUBE TECHNOLOGY L.2 - VARIABLE PRE-STRETCH CARRIAGE

Pre-stretch carriage with rollers controlled by two external direct-drive servo-motors.

Possibility to pre-stretch the film in variable way, in continuous and adjustable on HMI and apply up to 12 containment force values on the load.

The standard carriage is equipped with a 500/20" mm film reel height; optional carriage can be equipped with a 750/30" mm film reel height.

The adjustment of the containment force on the pallet is controlled by a PROACTIVE system based on the CUBE TECHNOLOGYTM Level 2.

EXACTLY the right amount of film EXACTLY in the correct position with EXACTLY the proper containment force

NIP&TUCK CLAMP

Optional device for clamping, cutting and threading the film without sealer.

The last tail of the wrapping film is inserted into the second-last wrap.

VERTICAL PRESSURE PLATEN

Pallet retainer system during wrapping, mandatory with upper covering systems (Top Inside / Top Outside) or with particularly unstable loads.

Air blowers are installed on the pressure platen plate to keep the film sheet in position.

TOP INSIDE COVER DEVICE

Automatic integrated in the structure system for covering the upper surface of the pallet and obtain protection against dust and water

TOP OUTSIDE COVER DEVICE

Automatic system for covering the upper surface of the pallet against dust.

It's an independent structure placed outside the machine, normally installed on the conveyor before wrapper position.

The top of the pallet is covered with the pallet in motion.

The device has electrical system integrated with the wrapping machine.

An electrical crane system (optional) is fixed on the top structure for easier reel replacement.

CENTER MACHINE PALLET LIFTER

Device to lift up the pallet in order to allow the wrapping of the wooden pallet.

It is normally used in combination with roping device to guarantee the maximum stability of the load

Available with pneumatic or hydraulic drive.

It is located under the central machine conveyor.

RCONNECT

Device for controlling, collecting, processing and filing large amounts of data from installed machines. Through a dedicated access-controlled portal, accessible from PCs or any portable device, you can connect to all machines equipped with the Rconnect system and monitor their performance 24/7.

- Monitor your performance

- Improve your efficiency

- Detect and inspect your line failures

- Remote assistance in private connection without need of company LAN

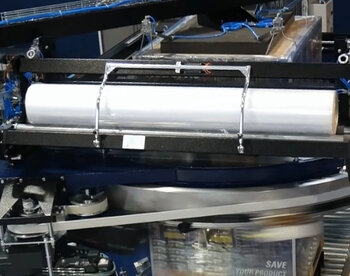

ARC - AUTOMATIC REEL CHANGER

Motorized unit to carry out, automatically and without any intervention of the operator, the ejection of the empty cardboard reel core and position the new reel of film for wrapping.

Available in the single ARC/1 with one spare reel and the ARC/2 version with two reels; compatible also with Top Inside.

The reel change units are positioned inside the perimeter protections, but outside the clearance of the ring and, therefore, it is possible to position the new reels in conditions of total safety without stopping the operation of the wrapping machine.

VCA - CORNER APPLICATOR

Automatic corner applicator device for the protection of the pallet corners.

It consists of vertical storages combined with vaccum grippers and moving hands.

Thanks to a special control system (ROBOPAC patent) the vacuum grippers are able to "locate" in a fully automatic way the corners of the pallet, without any manual setting or adjustment.

TPM KIT & TROUBLESHOOTING

LESS IS MORE

TPM kit means lower and preventive maintenance and higher productivity.

- Avoid production lines downtime

- Visual control of the machine status

- Faster troubleshooting (optional add-on that helps operators to solve eventual problems)

Easy lubrication operations, red/green colored rings manometers and maintenance schedule directly on HMI with indicators and warnings.

SLIPSHEET FOLDING DEVICE

Device to allow the wrapping of lower flaps on slip-sheets with or without wooden pallet.

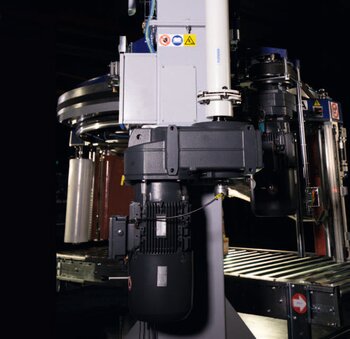

LOW-LEVEL MOTOR

Ring lifting motor in ergonomic position, no more needs of maintenance platforms.

MOBILE STOP KIT

Kit to allow top film positioning also on low pallets.

| Pallet dimensions min - max | mm |

400x600 - 1270x1270 |

inches | 16x24 - 50x50 | |

| Maximum pallet height | mm |

2000 |

inches | 80 |

| Standard power supply voltage and frequency | V - Hz |

400-415 ± 5% - 50 ± 1% |

| Optional power supply voltage and frequency | V - Hz |

380-480 ± 5% - 60 ± 1% |

| Compressed air pressure | Bar |

6 ± 1 |

| Film reel height | mm |

500 |

inches | 20 | |

| Max reel diameter | mm |

250 |

inches | 10 | |

| Optional film reel height | mm | 750 | inches |

30 |

brochure

related products

GENESIS THUNDER/2

Fully automatic hi-speed rotary ring wrapper with 2 reels

- ROTATING RING

- HIGH SPEED

HELIX MAX

Fully automatic rotating arm with two reels

- ROTATING ARM

- HIGH SPEED

HELIX 4/2

Fully automatic double rotary arm wrapper

- ROTATING ARM

- HIGH SPEED

case studies

PLZENSKY PRAZDROJ

Plzensky Prazdroj, another leading company that has chosen Robopac to modernise its packaging systems at the various manufacturing sites in the Czech Republic and Slovakia.

Logistics and end-of-line for Caviro

A complete end product handling system, spanning palletising to preparation of the shipping bays, all perfectly in synch with the automatic warehouse located onsite.

OCME and Robopac innovations for Mahou

Ocme and Robopac are working together to provide the best end-of-line solutions in the beverage sector to a key Spanish customer, Mahou.

Jafora entrusts OCME with palletizing and wrapping

Jafora is an important producer of soft drinks and juices from Israel, recognized worldwide for its technical expertise and its excellence in the research of the latest technological solutions for its plants.

Complete end-of-line for the tissue industry installed at FUTURA LINE

The customer's request was clear: to propose and design an automatic end-of-line system and logistic management of products on pallets, starting from a green field. OCME has been able to carry out this project by automating all the needs of the Italian Futura Line Group.