Prasmatic TC 300/400 PACK Wrap around packers for medium-speed productions

The TC 300/400 case packing machines range is the best solution for medium-speed productions in end-line packaging. Depending on the machine model, the type of packaging and characteristics of the product, the packaging speed of the TC 300/400 series ranges from 35 to 45 packages/min.

read more

PACKAGING MODELS

TC 300/400 T

The TC machines with carton-packing technology are available in the following versions:

TC 300: up to 35 packs/minute

TC 400: up to 45 packs/minute

Depending on the set-up, this series can realise all the classic secondary packaging solutions with carton tray.

|

|

|

packs in standard tray and full height tray |

packs in wrap-around carton |

product benefits

ERGONOMIC

Extremely ergonomic design.

FLEXIBLE

Maximum flexibility and efficiency.

ADAPTABLE

Easily adaptable to a wide range of production lines.

HMI

Userfriendly and wide touchscreen panel.

SAFE

Our top-brand brushless servomotor drives guarantee the highest safety and quality.

EASY MAINTENANCE

The led lighting and the sliding doors facilitate the access for cleaning and maintenance operations.

HIGH CAPACITY BLANK MAGAZINE

From 400 to 1600 according to thickness and magazine type.

STANDARD EQUIPMENTS

External Blank Magazine

The elevated ergonomics make it possible to load the blanks quickly and easily. The new structure set up orthogonally to the machine provides a great loading capacity and simplified adjustments. Possibility to choose between single and double version

Blanks Extraction

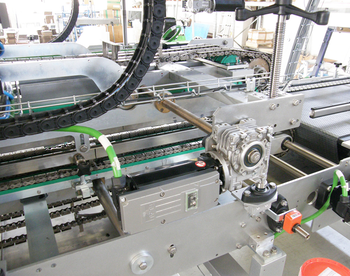

Carried out through a pick-up arm guided by a mechanical cam, that establishes the required rotation for the pick-up arm. Unit movement is controlled by a brushless motor, the blanks are positioned on the upstroke unit in line with the machine.

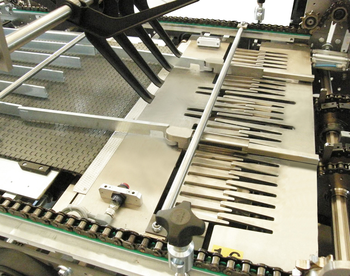

Product Separation

(TC300 model) Discontinuous Product Separation: separation system with mechanical control for medium speed productions. (TC400 model) Continuous Product Separation: separation system with electronic control for medium and high-speed productions.

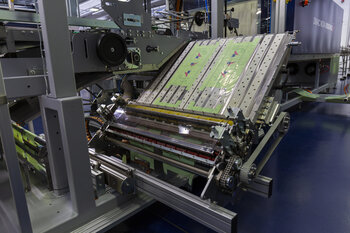

Product Wrapping Unit

Particularly suitable for high speeds and irregular shaped products with low stability, this device is controlled with a brushless motor and a linear guide with the function of guaranteeing correct and precise coupling of the product with the blank.

Film Reels

Various film reel positioning solutions are available, the ergonomics are particularly well-designed. Better access for format change operations and reel sealing means excellent man-machine interaction.

Machine Frame

Completely revisited, it is designed to offer multiple modular solutions based on machine configuration. The new frame offers better access to all of the units to operate the machine, change formats and perform maintenance.

overview

Depending on the set-up, this machine series can realise all the classic secondary packaging solutions with carton.

PRASMATIC TC 300/400 WRAP AROUND CASE PACKER

option & data sheet

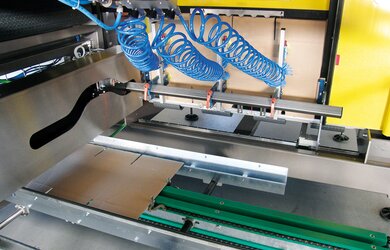

RETRACTABLE COLLATING PLATE

This solution offers high flexibility for the range of formats that can be produced, it also offers an excellent compromise when switching from tray packaging to packs with heat-shrink film only, and vice versa. The pneumatically-actuated surface offers the possibility of producing trays with high edges, it is particularly suited for the production of full height trays.

REMOVABLE FILM UNIT

The system offers easy access to the film unit, for quick and efficient maintenance. This application is particularly suited for liquid product sectors, such as dairy and beverage, where the primary packaging may break, possibly soiling the film.

Automatic reel change

The system seals and cuts the film in a fully-automated fashion without any operator intervention, this option makes it possible to continue without stopping film unwinding and the production cycle. The reel configuration is set up by the operator, through simple manual procedures.

Partial or full stainless steel

According to the customer's needs it possible to have a partial or a total stainless steel execution for the machine frame.

WASH DOWN EXECUTION

The Wash down application is particularly dedicated to all those sectors that require high hygiene quality standards, especially the dairy sector.

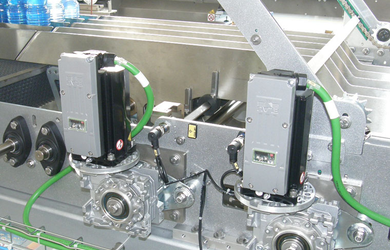

AUTOMATIC FORMAT CHANGE

For models with automatic format change, switching to the new format is carried out electronically through brushless motors, in most cases there is no need for tools or for the machine to be manned by the operator. Format change operations are carried out simply from the operator panel.

Easy film

External film group for reel loading that grants better access for format change operations and reel sealing means excellent man-machine interaction. The external reels option also offers automatic reel-change.

Standard Technical Features

| Blanks magazine capacity | 400-1600 according to thickness and magazine type |

| Max blank length | 1250 mm according to the speed and the machine model |

| Max blank width | 650 mm |

| Max reel diameter | 500 mm |

| Max reel width | 720 mm |

| Max reel weight | 80 Kg |

| Average size changeover time | 10 ÷ 12 min. according to the machine model |

| (*) Values are purely theoretical. We recommend contacting Prasmatic to assess the specific values for each project according to the products and materials used. | |

brochure

case studies

Medina dairy and Freshways invest in Robopac end of line solutions

Since merging in 2021, with Medina Dairies Ltd, Freshways is now one of the UK leading dairy suppliers, with a number of UK facilities combining to process over 500 million litres of milk per year.

USA: ROBOPAC AND TOPTIER BUILD SUNTADO'S NEW FOOD-DAIRY PLANT

Suntado, a leader in the co-packing of dairy beverages, has recently completed the installation of six secondary packaging lines at its plant in Burley, Idaho, made up of Robopac and Toptier solutions.