The international food & beverage industry is about to enter the showcase of excellence among this year's trade fairs. From 19 to 22 March 2024, the new edition of Anuga FoodTec will take place in Cologne (Germany), where the top players in the supply chain will be able to share the main innovations in process technology, filling technology, food safety, packaging, digitalization and intralogistics.

Aetna Group participates in the event on the strength of the acquisition made in 2022 of Meypack, a German company appreciated worldwide for the innovative capacity of its end-of-line products, with a particular focus on the food sector. An integration, between Meypack and the rest of the Group, that allows to strengthen a leadership position in the food & beverage segment thanks to the implementation of know-how and the penetration capacity that the Aetna Group's subsidiaries guarantee in the most important markets of the world and now also in Germany.

In Hall 8.1 | Stand A040 B059, the best and most advanced technologies will be showcased: an important testimony to the Group's commitment to ensure complete, versatile and competitive solutions, guaranteeing the principles of sustainability and quality required by a constantly evolving market.

The Robot S7 is among the flagships of the Aetna Group. The self-propelled robot for stretch wrapping under the Robopac brand name continues to reap success. Here it is presented in a full-optional version, including R-Connect technology for constant monitoring and optimization of production performance.

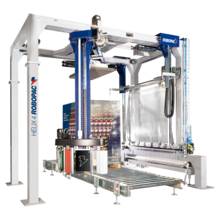

The word "flexibility" is echoed by Palwrapp, the compact, all-in-one palletizer with integrated stretch wrapper ideal for low-speed productions; for medium and high-speed production in end-of-line packaging, the ideal answer is the Prasmatic TC300 Combi combined shrink-wrapped and case packer, while the Helix 4 EVO automatic rotary arm wrapper combines the performance of previous generations to take efficiency to the next level.

Demonstrating the opportunities offered by the group when it comes to end-of-line automation, the OCME branded LGV range will accompany the show. Specifically, the Auriga S-Forklift with fixed forks will demonstrate its level of functionality for moving pallets in small warehouses without extremely heavy loads.

Packaging is well represented by Meypack's VP602 model, a case packer for packaging cases containing coffee capsules in display trays with lids, and by Sotemapack's WA20 for wrap-around cardboard packaging of trays for food products.

The company's green approach is also highlighted with two impactful solutions: the first is ReCYCLE, the machine for compacting and reducing the volume of packaging waste materials by up to 70%; the second is Technoplat 3000PWJ, an automatic wrapping station that uses paper as the wrapping material, embracing the policies of respect for the environment and sustainability.

Anuga FoodTec offers very important numbers for visitors: almost 1,600 exhibitors - more than 800 of them international - specialised and mostly manufacturers, offering the best available solutions for the future challenges of the sector. More than 40 thousand visitors from about 150 countries are expected to share and appreciate the most innovative aspects; numerous webinars, conferences and events, as well as a new exhibition area dedicated to environmental and energy technologies.