Aetna Group confirms its participation at MIAC 2024, the leading trade fair for the paper and tissue industry, which will take place in Lucca from 9th to 11th October. Visitors can discover the latest technological innovations and sustainable solutions from the Group's flagship brands Robopac and OCME at Stand B75.

MIAC - Mostra Internazionale dell'Industria Cartaria (International Paper Industry Exhibition) - stands out as a showcase of excellence, where numerous international companies come together to explore the most advanced technologies and to enrich their professional background. Aetna Group, a global leader in packaging solutions, is confirmed as a trusted partner for the industry, thanks to its long-standing experience and efficient and versatile packaging solutions, capable of guaranteeing high quality standards from the end of the line to the first stages of logistics.

Among the most eagerly awaited innovations is OCME's RDM 2.0 platform, a state-of-the-art solution that revolutionises data management in production, offering a significant upgrade for automated lines. RDM 2.0 shifts from Remote Data Monitoring to Remote Device Management, thus redefining the boundaries of supervision and control of converting lines.

This advanced monitoring system gives an extraordinary competitive advantage, enabling timely interventions to optimise production lines. In addition, the platform is designed to ensure maximum product traceability and impeccable labelling, guaranteeing perfect machine parametrisation. The system performance analysis, made possible by the data collected, identifies areas for improvement and implements targeted measures to increase production efficiency and OEE (Overall Equipment Effectiveness). In addition, it will be possible to identify critical energy consumption points, taking measures to minimise environmental impact and thus contributing to corporate sustainability goals.

MIAC will also be an opportunity to present the Group's achievements and strategies in terms of sustainable growth, with a focus on solutions combining energy efficiency, packaging material reduction and technological innovation. The adoption of the Internet of Things (IoT) and Digital Twin allows, for example, advanced operations monitoring and the creation of virtual replicas aimed at optimising machine performance.

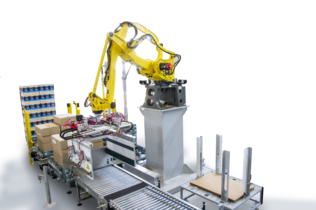

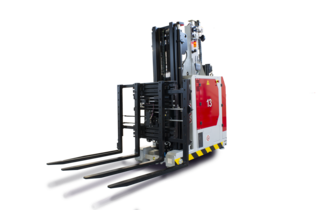

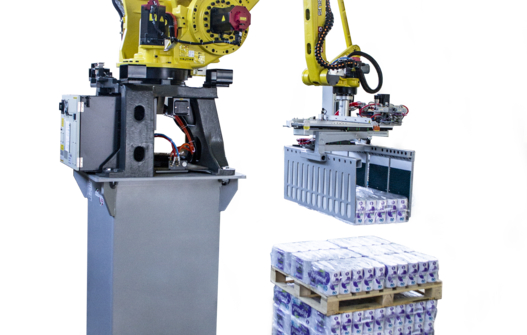

During MIAC, visitors will have the opportunity to learn more about the Group's solutions, according to the Industry 5.0 requirements: from palletising and intralogistics systems to pallet wrapping and packaging, designed to ensure maximum protection and load stability.

Laser-guided vehicles (LGVs) and advanced simulation software for pallet configuration will be of particular interest. These innovations significantly improve production efficiency, reduce transport time and minimise errors, and promote a continuous and safe flow of materials.

OCME and Robopac are distinguished for their constant innovation and commitment to sustainability and digitisation. The advanced technologies developed in the TECHLAB™, the most advanced research laboratory system in the packaging industry and an integral part of the Aetna Group, are fundamental to this journey. Thanks to the tests carried out in the laboratories, Robopac and OCME can customise solutions according to the specific needs of customers and their sector, offering a unique competitive advantage that always integrates the ecological aspect.