Aetna Group at MIAC 2025: Innovation and Specialization serving the Tissue & Paper industry

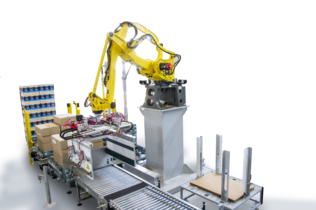

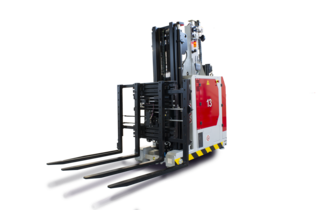

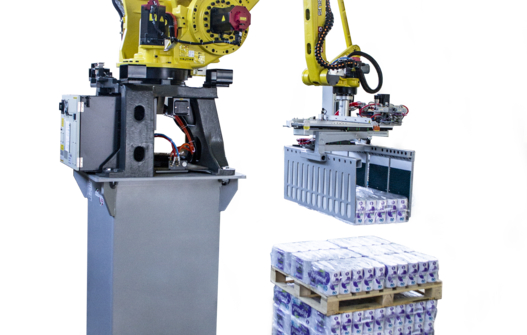

On the occasion of MIAC, Aetna Group presents its strategic commitment to the Tissue & Paper sectors, supported by a complete and integrated range of dedicated solutions, the result of continuous investment in R&D. From OCME’s palletizing and intralogistics, to Robopac’s stretch-wrapping, and Sotemapack’s packaging solutions, the Group’s offering stands out for specialization and versatility—features that MIAC visitors will be able to see firsthand in Lucca, Italy, from October 8 to 10, at booth B68.

With extensive experience in the sector, Aetna Group provides innovative solutions for handling delicate materials and heterogeneous formats, ensuring maximum protection and stability in every end-of-line phase. The technologies developed meet the needs of a constantly evolving industry, delivering high performance, precise handling of packages—even at high speed—and optimized pallet configurations: results achieved also thanks to advanced simulation software.

A clear example of this is the introduction of OCME’s new RDM (Remote Data Monitoring): a modular and scalable IIoT (Industrial Internet of Things) platform that transforms production data into strategic value.

RDM adapts to different customer needs, offering both a full-Edge version—for those who wish to keep data management local—and a Cloud version for centralized, multi-plant management. Compatible with multi-brand automation systems thanks to standard OPC-UA and MQTT protocols, RDM establishes itself as an intelligent ecosystem that enhances existing investments and breaks down technological barriers.

The platform enables advanced monitoring of KPIs and consumption, integrates business intelligence and predictive maintenance tools, and introduces AI agents that simplify data analysis, improve performance over time, and make process management accessible even to less experienced operators.

With RDM, OCME offers not just a technology, but a strategic partnership aimed at reducing costs, improving efficiency, and accelerating the transition towards more sustainable and digitalized production models.