Auriga stabilizer

Laser guided vehicles equipped with load stabilizers

Auriga Power stacker

Laser guided vehicle with reduced dimensions

AGV (Automated Guided Vehicle) refers to vehicles that move and perform tasks autonomously, similar to human-operated forklifts. Used across all manufacturing sectors, AGVs transport a wide range of products.

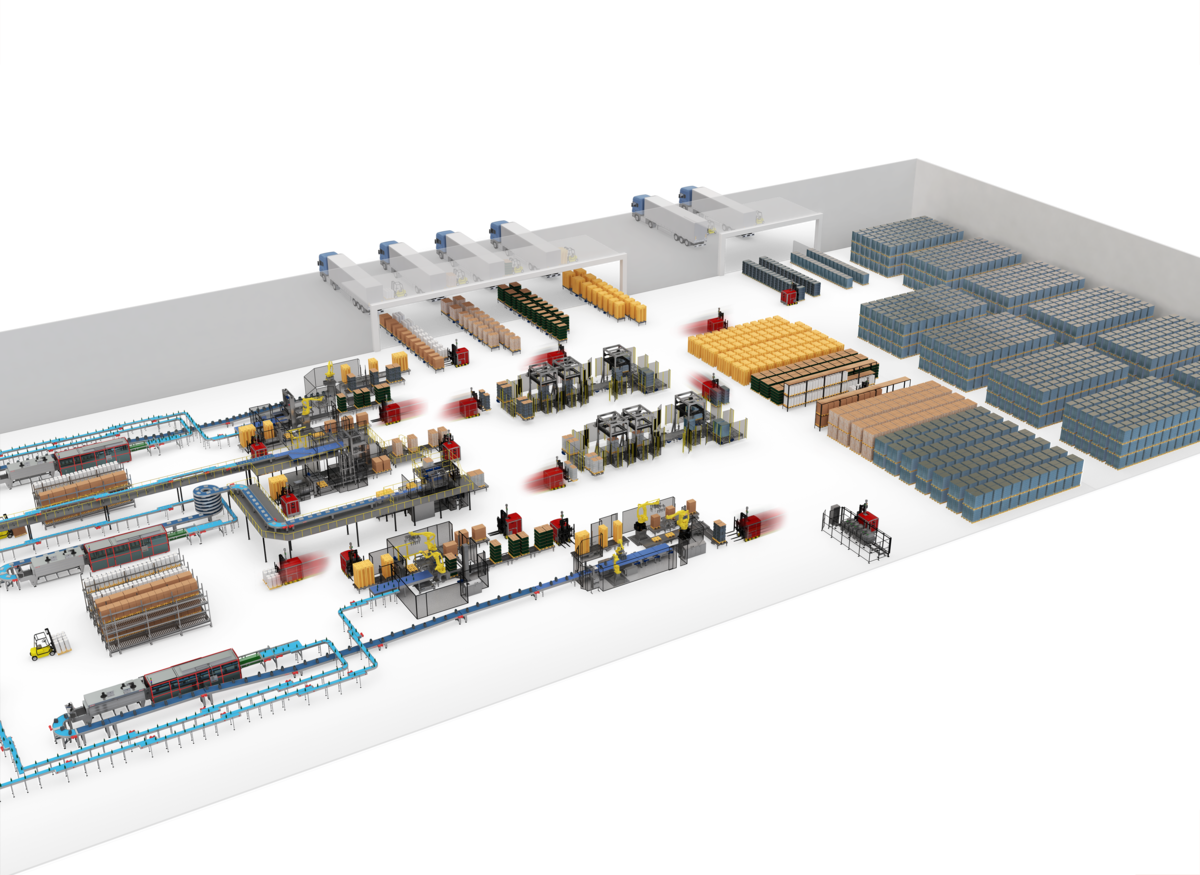

With extensive experience and highly reliable machines, we support any layout—even with the fastest, most advanced reel rewinders.

Laser Guided Vehicles (LGV) offer high precision, flexibility, and speed. A laser sensor reads three wall-mounted reflectors to determine the vehicle's position within millimetres. Unlike floor-fixed systems, LGVs can move freely and adapt routes via software—handling floor irregularities with ease.

Fast ROI: Automated systems typically pay for themselves in just two years, ensuring excellent financial efficiency.

Laser guided vehicles equipped with load stabilizers

Laser guided vehicle with reduced dimensions

With thousands of AGVs deployed worldwide, OCME continues to lead in automated intralogistics innovation, backed by decades of engineering excellence and global support infrastructure.

Perfect for Beverage & Food Processing, Chemical & Lubricants Industry, Logistics & Distribution Centres, Manufacturing Plants, High-Speed Filling & Packaging Lines

The company decided to rely on OCME's automatic solutions, to improve the performance of its warehouse and the working environment. The answer given by OCME in order to meet the needs of the industrial lay-out was providing two Auriga high-precision LGV lift trucks

A complete end product handling system, spanning palletising to preparation of the shipping bays, all perfectly in synch with the automatic warehouse located onsite.

OCME supplied Enoitalia with 11 automatic Laser Guided Vehicles (LGV) of the Auriga series, which includes two models.

The value of flexible plastic packaging for the European food and non-food consumer market bears the SIT Group brand, one of the leading players in flexible packaging.

The customer's request was clear: to propose and design an automatic end-of-line system and logistic management of products on pallets, starting from a green field. OCME has been able to carry out this project by automating all the needs of the Italian Futura Line Group.